Fast and Simple Way to Make Highly Ordered Porous Films

Osaka-based researchers develop one-step method to coat centimeter-sized inorganic substrates with fully aligned metal–organic framework films

Metal–organic frameworks, or MOFs, are highly ordered crystalline structures made of metal ion nodes and organic molecule linkers. Many MOFs can take up and store gases, such as carbon dioxide or hydrogen, thanks to their porous, sponge-like structures.

MOFs are also potential chemical sensors. They can be designed to change color or display another optical signal if a particular molecule is taken up into the framework. However, most studies on MOFs are performed on tiny single crystals, which is not practical for the commercial development of these materials.

Chemists have now come a step closer to making commercially viable sensors that contain highly ordered MOFs, thanks to the collaboration of an international team of researchers at Osaka Prefecture University, Osaka University and Graz University of Technology. The method will allow researchers to fabricate large tailor-made MOF films on any substrate of any size, which will vastly improve their prospects for commercial development.

In a study recently published in Nature Materials and highlighted on the cover and in the ‘News and Views’ section of the journal, the Osaka-based researchers report a one-step method to prepare thin MOF films directly on inorganic copper hydroxide substrates. Using this method, the researchers produced large MOF films with areas of more than 1 cm 2 that were, for the first time, fully aligned with the crystal lattice of the underlying substrate.

Noting that microcrystals of copper hydroxide can be converted into MOFs by adding organic linker molecules under mild conditions, the researchers used the same strategy to create a thin MOF layer on larger copper hydroxide substrates. They carefully chose the carboxylic acid-based linker molecule 1,4-dibenzenedicarboxylic acid because it fit exactly to the spacing between the copper atoms on the substrate surface.

A MOF film began to grow on the copper hydroxide substrates within minutes of mixing it with the linker molecule, making this technique much easier and faster than previous step-wise approaches to build up MOF films. Using microscopy and X-ray diffraction techniques, the researchers found that the film was precisely oriented along the copper hydroxide lattice.

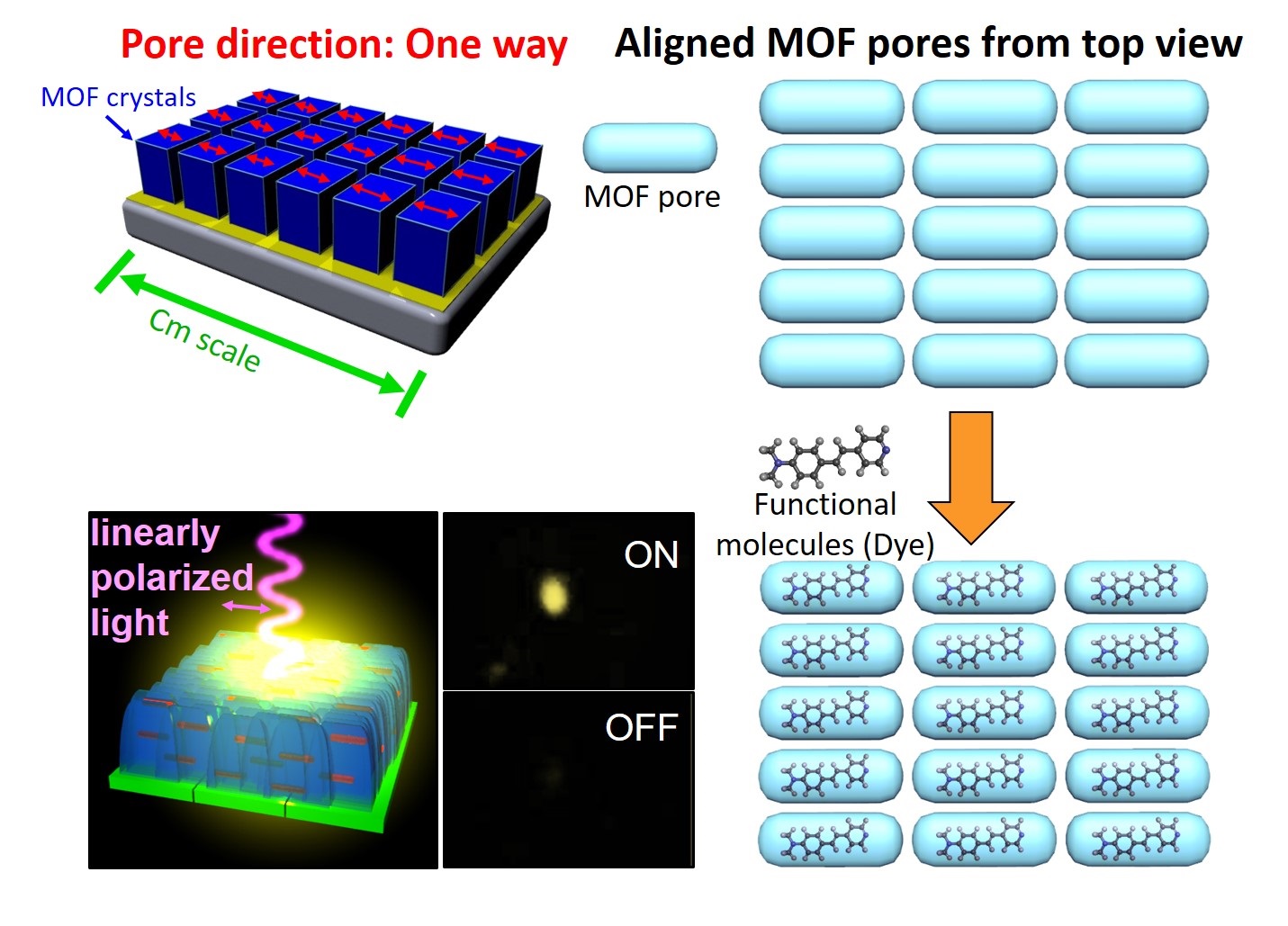

To demonstrate the unique optical behavior of their films, the researchers filled the MOF’s ordered pores with fluorescent molecules, which fluoresce when light is shone on them in a particular direction. When they shone polarized light on the ordered material, the researchers found that they could easily switch the fluorescence response on or off simply by rotating the material.

Abstract

The fabrication of oriented, crystalline films of metal–organic frameworks (MOFs) is a critical step toward their application to advanced technologies such as optics, microelectronics, microfluidics and sensing. However, the direct synthesis of MOF films with controlled crystalline orientation remains a significant challenge. Here we report a one-step approach, carried out under mild conditions, that exploits heteroepitaxial growth for the rapid fabrication of oriented polycrystalline MOF films on the centimetre scale. Our methodology employs crystalline copper hydroxide as a substrate and yields MOF films with oriented pore channels on scales that primarily depend on the dimensions of the substrate. To demonstrate that an anisotropic crystalline morphology can translate to a functional property, we assembled a centimetre-scale MOF film in the presence of a dye and showed that the optical response could be switched ‘ON’ or ‘OFF’ by simply rotating the film.

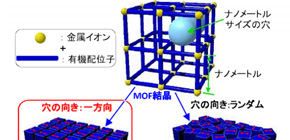

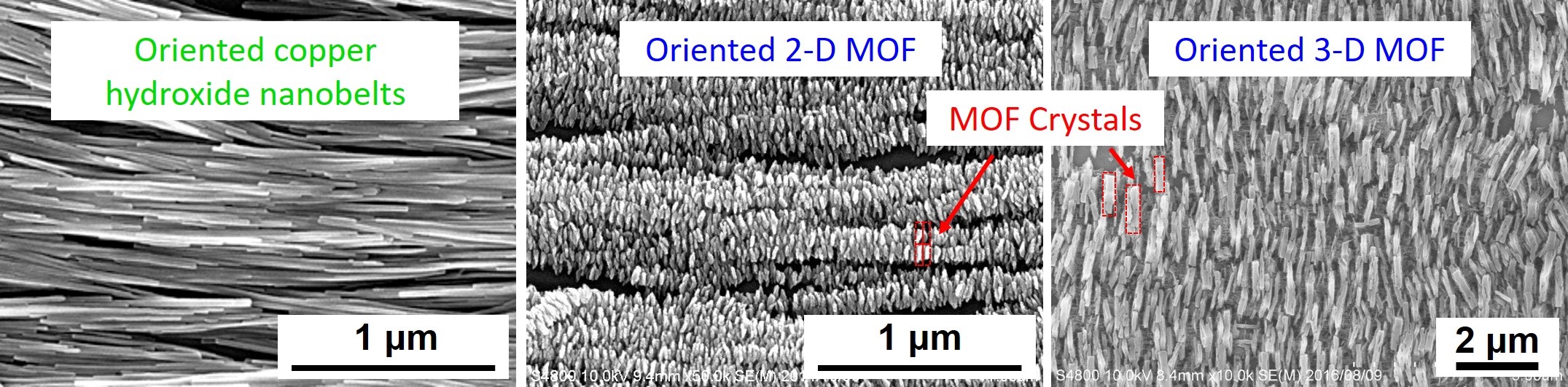

Figure 1. In the present study, we found a method to fabricate Metal organic framework (MOF) films where the nanometer scale pores of MOF were aligned in the same direction. Nano porous films reported so far are composed of randomly oriented crystals (no pore alignment) (the right image). On that film, it is impossible to get high functionality from functional molecules in nanopores because the direction of molecules is different between each crystals. On the other hand, oriented MOF films reported here can incorporate functional molecules with alignment into the nanopores, which allows us to get high functionality from molecules and then possibly fabricate high performance electrical and optical devices.

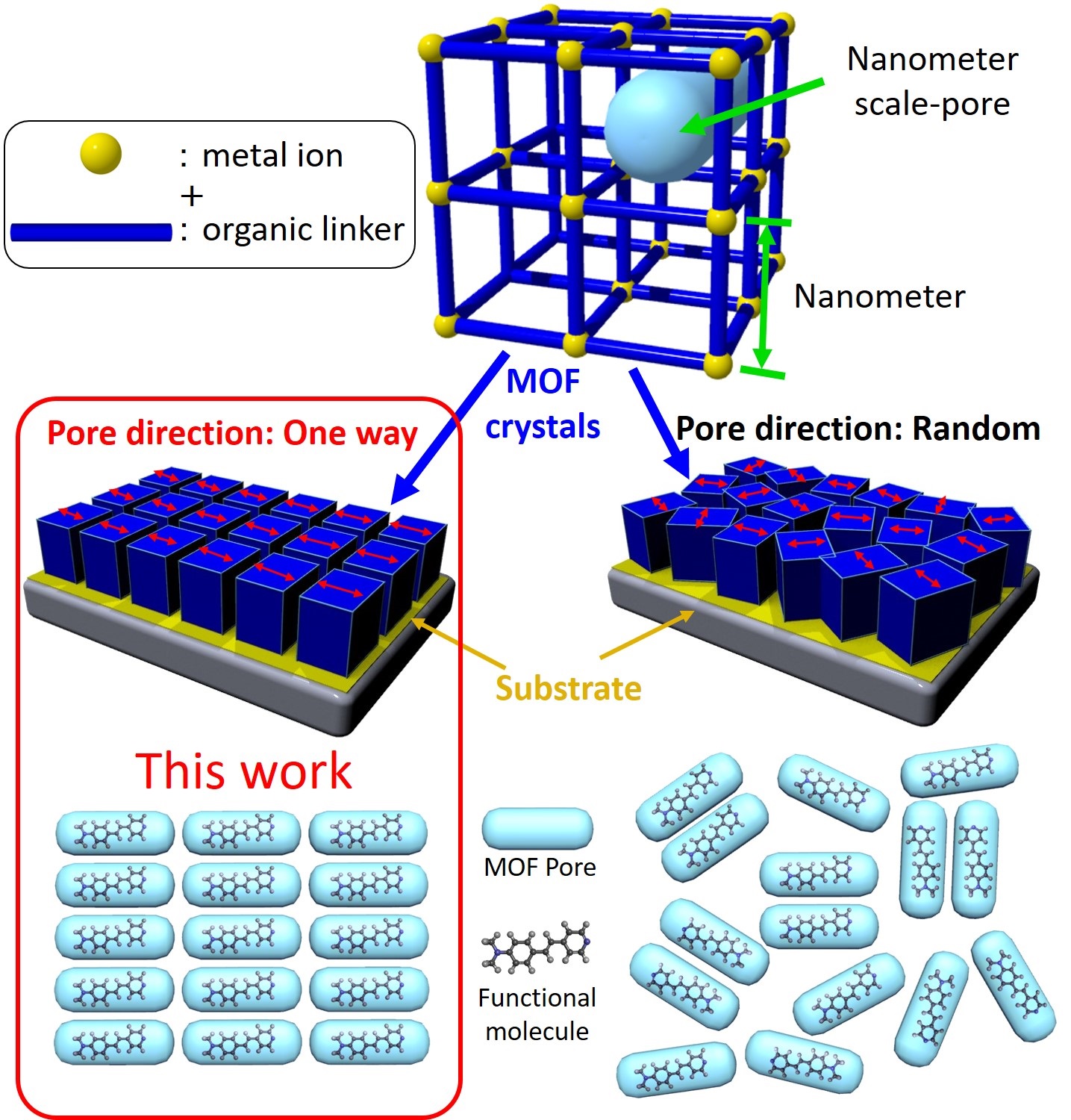

Figure 2. Electron microscopy images of oriented copper hydroxide nanobelts used as a substrate for heteroepitaxial growth of MOF (left), Epitaxially-growth 2-dimensional MOF crystals on oriented copper hydroxide nanobelts (middle), Epitaxially-growth 3-dimensional MOF crystals on oriented copper hydroxide nanobelts (right).

Figure 3. Alignment of guest molecules in an oriented MOF film. All the molecules are aligned with same direction on the entire film (centimetre-scale). High performance for electrical and optical applications is expected because the all aligned molecules show same response against external stimulus at same time. In the present study, a centimetre-scale MOF film in the presence of a dye showed that the optical response could be switched ‘ON’ or ‘OFF’ by simply rotating the film (left below).

To learn more about this research, please view the full research report entitled “ Centimetre scale micropore alignment in oriented polycrystalline Metal-Organic Framework films via hetero-epitaxial growth ” at this page of the Nature Materials website.

Related link