Metathesis reaction at 70°C achieved using new catalyst

Will improve energy efficiency in the industrial process

Olefin metathesis is an organic reaction that recombines carbon-carbon double bonds in molecular conversion of an alkene, an unsaturated hydrocarbon that contains at least one carbon–carbon double bond, and is one of the reactions necessary for building a carbon skeleton. Additionally, in Olefins Conversion Technology (OCT), the biggest industrial process for manufacturing propene, heterogeneous catalysts such as silica-supported tungsten oxide catalysts (WO 3 /SiO 2 ) are used. In this way, WO 3 /SiO 2 is important in industry; however, its catalytic activity is significantly lower than that of homogeneous catalysts.

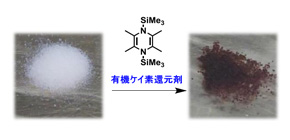

A group of researchers led by Professor MASHIMA Kazushi and Associate Professor TSURUGI Hayato at the Graduate School of Engineering Science, in a joint research project with a group of researchers led by Professor Christophe Copéret at ETH Zürich, and Dr. Olga Safonova at Paul Scherrer Institute, succeeded in generating super active olefin metathesis reactions by reduction of silica-supported tungsten oxide catalysts by silicon compound. While high temperatures over 400°C were necessary for conventional methods using solid catalysis in the industrial process, the method developed by this group has made it possible to efficiently promote the metathesis reaction at 70°C.

This group’s research results have made it possible to evenly support tungsten oxide on the surface of silica and observe its detailed structure by conducting various optical measurements using surface organometallic chemistry (SOMC) technology that bridges the gap between homogeneous and heterogeneous catalysis. This group also succeeded in generating more highly active species than conventional catalysts under very mild conditions of 70°C through the use of organosilicon reducing agents that do not generate metallic salts.

Furthermore, by analyzing a catalytic active species and catalysts after reaction, this group experimentally clarified for the first time that the catalytic active species was formed by tungsten (IV) generated after reduction. By thoroughly examining the state of this catalyst before and after reduction as well as at each stage after the catalytic reaction, this group clarified the mechanism for generation of catalytic active sites. This group also showed the possibilities that this catalyst can become a practical metathesis catalyst because it is possible to be used for conventional general catalysis systems through reactivation of inactive catalysts by using organosilicon reducing agents. It is expected that this method will improve energy efficiency in the industrial process and develop the innovative synthesis of functional organic molecules such as physiologically active substances and functional polymers by making use of this catalyst’s mild reactive conditions.

Abstract

Alkene metathesis is a widely and increasingly used reaction in academia and industry because of its efficiency in terms of atom economy and its wide applicability. This reaction is notably responsible for the production of several million tons of propene annually. Such industrial processes rely on inexpensive silica-supported tungsten oxide catalysts, which operate at high temperatures (>350 °C), in contrast with the mild room temperature reaction conditions typically used with the corresponding molecular alkene metathesis homogeneous catalysts. This large difference in the temperature requirements is generally thought to arise from the difficulty in generating active sites (carbenes or metallacyclobutanes) in the classical metal oxide catalysts and prevents broader applicability, notably with functionalized substrates. We report here a low temperature activation process of well-defined metal oxo surface species using organosilicon reductants, which generate a large amount of active species at only 70 °C (0.6 active sites/W). This high activity at low temperature broadens the scope of these catalysts to functionalized substrates. This activation process can also be applied to classical industrial catalysts. We provide evidence for the formation of a metallacyclopentane intermediate and propose how the active species are formed.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

To learn more about this research, please view the full research report entitled “ Low Temperature Activation of Supported Metathesis Catalysts by Organosilicon Reducing Agents ” at this page of the ACS Central Science website.

Related links