Elucidated the deformation behavior of high-strength hierarchical structures unique to metal 3D printing!

New control technology that dramatically improves the mechanical properties of metal components

- The deformation behavior and strengthening mechanism of a unique high-strength hierarchical structure consisting of a crystallographic lamellar microstructure (CLM) and a nanometer-scale cellular structure, which can only be obtained by metal 3D printing (3DP) has been clarified.

- Discovered that the macroscopic strength of the entire molded body is determined by the strength of the narrow (low volume fraction) sublayers, and that two types of cellular structures with different morphologies cause refinement strengthening in response to thermal effects, establishing a technology for artificially controlling the cellular structure morphology which previously was impossible.

- This novel mechanical properties control method is expected to significantly improve the mechanical properties of metal components in a wide range of industries, including aerospace, energy, transportation equipment, and medical equipment.

Outlines

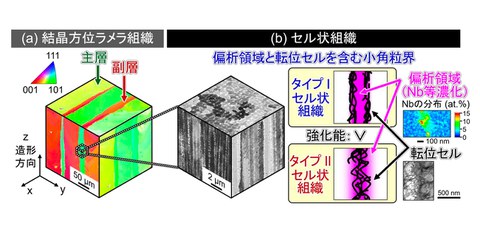

A research group including Associate Professor Ken Cho, Kippei Yamashita (doctoral student), Professor Hiroyuki Yasuda, and Professor Takayoshi Nakano of the Graduate School of Engineering at the University of Osaka has, for the first time, elucidated the deformation behavior and strengthening mechanism of a high-strength hierarchical structure consisting of a crystallographic lamellar microstructure (CLM) (Fig. 1(a)) and a nanometer-scale cellular structure (Fig. 1(b)), which is formed by the ultra-rapid solidification and cooling phenomenon unique to metal 3D printing.

Until now, the deformation behavior and strengthening mechanism of these structures, as well as the detailed morphology and formation mechanism of the cellular structure, have not been fully elucidated, and nobody has been able to propose an optimal organizational morphology or achieve artificial control.

In this research, the researchers focused on the hierarchical structure formed in a Ni-based superalloy produced by metal 3D printing, and by individually analyzing the deformation behavior of the wide main layer (layer with a high volume fraction) and the narrow sublayer (layer with a low volume fraction) in the CLM using in-situ neutron diffraction (ND), they found that the macroscopic strength of the entire molded body is determined by the strength of the sublayer, which is narrower than the main layer. Furthermore, they discovered that the cellular structure is a low-angle grain boundary (LAGB) consisting of segregated region where specific elements are concentrated and dislocation cells where dislocations accumulate. They also found for the first time that two types of cellular structure (Fig. 1(b)) with different morphologies of segregated regions and dislocation cells are formed depending on the thermal influence from the molten pool, which is determined by the process conditions (laser output, a scan speed, etc.) during metal 3DP manufacturing, and that each type results in refinement strengthening with different strengthening capabilities. In addition, the research group investigated the morphology of cellular structures by conducting nanometer-scale structural analysis, and by analyzing the thermal history of the molten pool using computational methods, they elucidated its morphology mechanism. They have established a technology for artificially controlling the morphology of cellular structures based on controlling the cooling rate of the molten pool and the temperature distribution formed around it.

Thus, this novel mechanical properties control method, which combines a new strengthening mechanism derived from a cellular structure with the special deformation behavior of CLM, is a groundbreaking technique for achieving high mechanical properties that could not be achieved by conventional methods. Through the creation of high-mechanical property components, it is expected to contribute to the weight reduction, low fuel consumption, and efficiency improvement of equipment and systems in a wide range of areas, as well as improved durability and safety.

Fig. 1 Unique hierarchical structure observed in a Ni-based superalloy fabricated by metal 3D printing.

(a) Micrometer-scale crystallographic lamellar microstructure (CLM) (b) Nanometer-scale cellular structure. There are two types of cellular structure with different morphologies of segregated regions and dislocation cells. Both cellular structures produce refinement strengthening but Type I cell has a higher strengthening capacity. Credit: Hiroyuki Yasuda

Research Background

Ni-based superalloys, a type of high-temperature resistant alloy, have excellent high-temperature strength and oxidation resistance, and are therefore widely used in high-temperature environments such as aircraft jet engines and turbine generators. In recent years, efforts to achieve carbon neutrality and green innovation have been strengthened in various fields around the world. In response to this, there is an urgent need to improve the efficiency and durability of these devices and systems, and there is a strong demand for even higher strong alloys. In such a social situation, the research team has reported that by using the laser powder bed fusion (L-PBF), a type of metal 3DP, to produce Ni-based superalloy bodies, a unique hierarchical structure consisting of a micrometer-scale (one millionth of a meter, μm) CLM structure and a nanometer-scale (one billionth of a meter, nm) cellular structure can be obtained, resulting in strength approximately 50% higher than conventional materials (Acta Materialia 212 (2021) 116876). Establishing a novel mechanical properties control method that utilizes the hierarchical structure that can only be obtained through metal 3DP is expected to lead to the development of the strengthening of Ni-based superalloys. However, the deformation behavior and strengthening mechanism of this type of structure, as well as the detailed morphology and formation mechanism of the cellular structure, have not been elucidated, and it has not yet been possible to propose an optimal morphology or to artificially control it.

Therefore, in this study, the researchers combined experimental techniques, such as nanometer-scale structural analysis and in-situ neutron diffraction analysis using neutron diffraction (ND) technique, with computational techniques, such as thermo-fluid dynamics calculations and crystal plasticity finite element method (FEM), to clarify the deformation behavior of the main and sublayers in the unique hierarchical structure, the strengthening mechanism due to the cellular structure, and the formation mechanism of the cellular structure, with the aim of establishing a technology for artificially controlling the morphology of the cell structure.

Research Contents

By using the L-PBF method, the research group fabricated Ni-based superalloy (Inconel 718) molded bodies. The fabricated object has a crystallographic lamellar microstructure (CLM) in which two regions with different crystal orientations (main layer: a layer approximately 55 μm wide with an orientation in the fabricate direction (green arrow in Fig. 1(a)), and sublayer: a layer approximately 25 μm wide with an orientation in the fabricate direction (red arrow in Fig. 1(a)) are stacked in one direction. Furthermore, within each layer, cylindrical cellar structures are formed at intervals of approximately 400 to 600 nm (Fig. 1(b) white).

To understand the deformation behavior of CLM structure, the research group attempted to analyze the changes in lattice strain during deformation of the main layer and sublayer individually using in-situ neutron diffraction (ND) (BL19 TAKUMI at the J-PARC Center) (Fig. 2). The results clarified that the stress at which the sublayer begins plastic deformation is higher than that of the main layer. This is caused by the difference in elastic modulus between the main layer and the sublayer due to the difference in crystal orientation. The stress at which plastic deformation begins in this sublayer corresponds to the macroscopic strength of the entire structure. The research group demonstrated that this indicates that the CLM structure exhibits unique deformation behavior in which the strength of the narrow sublayer determines the overall strength. This suggests that the strength of the fabricated object can be increased by improving the strength of the sublayer.

Then, the cellar structure in the sublayer was analyzed. The results are found to be low-angle grain boundaries (LAGB) containing segregated regions where specific elements such as niobium (Nb) are concentrated and dislocation cells. This cellar structure is formed due to the ultra-rapid solidification and cooling phenomenon in the L-PBF method, where the cooling rate reaches 107 K/s (approximately 10 million degrees per second). Furthermore, a more detailed investigation of the segregated regions and dislocation cells in the cellar structure revealed the existence of two types of cellar structure, which differ in the Nb concentration and the position of the dislocation cells in the segregated region (Type I cell: dislocation cells at the edge of the segregated region with high Nb concentration, and Type II cell: dislocation cells within the segregated region with low Nb concentration) (Fig. 1(b)). The type II cell structure is a change from type I cell due to the mitigation of the concentration of Nb and other elements in the segregated region caused by the thermal effect resulting from the temperature distribution around the molten pool determined by process conditions such as the laser power and scanning speed, which are the heat source. Based on this understanding, the research group established a technology to control the cooling rate and the thermal influence of the molten pool by controlling the laser energy density during fabrication, thereby artificially controlling the cell spacing and creating Type I and Type II cellar structures (Fig. 3(a)). The researchers then investigated the effect of the cellar structure on the strength of the sublayer, and found that the narrower the cell spacing, the higher the strength resulting from refinement strengthening, and that Type I cell structure has a higher strengthening capacity (Fig. 3(b)). Since it has previously been thought that LAGBs are not involved in strengthening, this new strengthening mechanism caused by cellar structures is a discovery of great academic interest.

The novel mechanical properties control method developed in this study, which utilizes metal 3DP with a property of “superimpose a new strengthening mechanism derived from a cellar structure on the special deformation behavior of a CLM structure,” is a groundbreaking method that realizes high mechanical functions that cannot be achieved by conventional methods.

Fig. 2 Analysis of lattice strain changes in each layer during deformation using in-situ neutron diffraction (ND). In stage I, both layers undergo elastic modules (linear increase in lattice strain).

In stage II, the main layer begins to undergo plastic deformation first (the linear increase in lattice strain slows down), while the sublayer continues to undergo elastic deformation.

Credit: Hiroyuki Yasuda

Fig. 3 High strength achieved by artificially controlled cellar structure

(a) Control of cell spacing, focusing on the cooling rate of the molten pool. The faster the cooling rate, the narrower the cell spacing.

(b) Relationship between cell spacing and hardness of each layer. The narrower the cell spacing, the higher the strength. The Type I cellar structure has a larger slope (k) and a higher strengthening capacity than the Type II cellular structure.

Credit: Hiroyuki Yasuda

Social Impact of the Research

The hierarchical structure spotlighted in this research can be introduced into primary structural materials such as stainless steel and titanium alloys, as well as next-generation structural materials such as high-entropy alloys by utilizing metal 3DP. Therefore, novel mechanical properties control method established in this research will contribute to a significant improvement in the mechanical functions of metal components not only in the aerospace and energy fields, where Ni-based superalloys are widely used, but also in a wide range of industrial fields, such as the transportation equipment, including automobiles, which is one of Japan's important industries, and the medical equipment, where demand is steadily increasing worldwide. To date, metal 3DP has been developed as a technology for controlling the complex internal and external shapes of metal components. The results of this study demonstrate that metal 3DP is effective in controlling the structure and even the mechanical functions of metal components and are expected to lead to an expansion of the scope of using metal 3DP in industry. Furthermore, the creation of highly mechanically functional components based on this study result is expected to contribute greatly to the realization of a sustainable society by reducing the weight of equipment and systems, low fuel consumption and efficiency, durability and safety improvement.

Notes

The article, “Effect of nanoscale cellular structure on the mechanical properties of Inconel 718 with unique hierarchical structure fabric,” was published in Acta Materialia at DOI: https://doi.org/10.1016/j.actamat.2025.121696