You don't have to eat margarine to know its texture!

Development of analytical technology to quantitatively evaluate the microstructure of margarine, such as the emulsification state, which determines the texture of margarine.

- Evaluation of margarine quality and emulsification state based on quantitative analysis of compounds/ions using Raman imaging and machine learning.

- Visualization of the effect of manufacturing process and length of storage on the microstructure of margarine

- Provides an evaluation method to search for manufacturing processes with qualities required by manufacturers, such as no oil off, excellent texture, and high functionality.

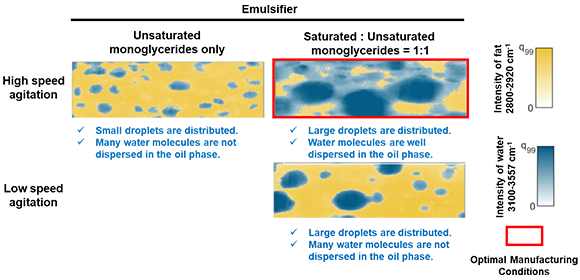

Quantitative visualization of the effects of manufacturing processes and emulsifiers on the emulsification state of margarine.

Figure adapted and modified from Taylor et al. (2024), Food Chemistry (CC-BY 4.0).

Outline

Researchers from the Photonics and Biosensing Open Innovation Laboratory of National Institute of Advanced Industrial Science and Technology (AIST) , including J. Nicholas Taylor, Senior Researcher; Kazuki Bando, Invited Researcher; Satoshi Fujita, Deputy Laboratory Director; Professor Katsumasa Fujita, Graduate School of Engineering, Osaka University; Shiori Tsukagoshi, Research Scientist, Leo Tanaka, Chief Researcher, MEGMILK SNOW BRAND Co., Ltd. developed an analytical technique to evaluate the quality and emulsification state of margarine based on quantitative analysis of compounds/ions using Raman imaging and machine learning.

The newly-developed analysis method is expected to be used not only to control the texture of margarine, but also for practical quality evaluation and product improvement. It is also expected to be a powerful tool not only for margarine, but also for the inspection of food products containing large amounts of liquid components.

Details of this technology were published in Food Chemistry on November 20, 2024.

Margarine is manufactured by emulsifying vegetable oils and fats, and the type and ratio of emulsifiers and the manufacturing process have a significant impact on the texture and appearance of the margarine. In order to control the state of emulsification and optimize the process to produce margarine to manufacturer specifications, such as limiting oil seepage, producing smoother textures, and increasing functionality, analytical methods to quantitatively evaluate the microstructure and molecular distribution of margarine are required.

In this study, we used Raman imaging and machine learning to visualize how the microstructures and molecular distributions of margarine change in response to parameters that affect quality, such as emulsifier content, manufacturing process, and shelf life, to quantitatively evaluate the quality of margarine using a chemical method. The results of this study showed that margarine quality was evaluated based on quantitative analysis of compounds/ions. The results revealed that hydrogen bonds formed in the oil phase are positively correlated with oil-off, and also provided a quantitative interpretation of how conditions in the manufacturing process affect margarine microstructure, molecular distribution, and oil-off. It is believed that this technology can be used by margarine manufacturers as a practical quality evaluation technique for quality control and modification.

Social Background of Development

Margarine is manufactured by emulsifying vegetable oils and fats, and the manufacturing formulation and process, including the oil and water content, the type and ratio of emulsifiers, and the stirring speed during production, have a significant impact on the texture and appearance. For example, when a smoother, more palatable margarine is produced, the formulation yields a margarine that cannot maintain its emulsified state, causing liquid oil to seep from the mixture, a phenomenon known as oil-off. Conversely, if the formulations and processes are modified to produce a strengthened crystalline network of fats and oils that prevents oil off, the margarine product tends to be hard with a poor texture. Additives may also be introduced to margarine production to achieve higher functionality, but some additives adversely affect the emulsification state, so the ingredients and manufacturing process need to be reconsidered.

As described above, in order to control the state of emulsification and optimize the production of margarine to manufacturer specifications such as little or no oil-off, smoother texture, and high functionality, a method to quantitatively evaluate the microstructure and molecular distribution of margarine is necessary. Until now, however, the main evaluation methods have been observation of the crystal structure of margarine using optical or electron microscopes and measurement of its solidity and viscosity. There is no method for directly imaging and quantitatively analyzing information on the margarine surface microstructure and molecular distribution, and the development of a new method has been desired.

Paper Information

Journal: Food Chemistry

Title of paper: Microscopic Water Dispersion and Hydrogen-Bonding Structures in Margarine Spreads with Raman Hyperspectral Imaging and Machine Learning

Author: J. Nicholas Taylor, Kazuki Bando, Shiori Tsukagoshi, Leo Tanaka, Katsumasa Fujita, Satoshi Fujita