Getting warmer: Improving heat flux modeling

Researchers at Osaka University use a computer simulation to model to flow of heat at the surface of a solid–liquid interface with atomic resolution, which may help in the development of novel nanoscale manufacturing methods

Scientists at Osaka University have simulated heat transport at the smallest scales using a molecular dynamics computer simulation. By studying the motions of the individual particles that make up the boundary between a solid and a liquid, they have been able to calculate heat flux with unprecedented precision. This work may lead to significant improvements in our ability to fabricate nanoscale devices, as well as functional surfaces and nanofluidic devices.

The process by which heat is transferred at the point where a solid meets a liquid may seem to be a simple physics problem. Traditionally, macroscopic quantities - such as density, pressure, temperature, and heat capacity - were used to compute the rate at which thermal energy moves between materials. However, properly accounting for the motion of individual molecules, while observing the laws of conservation of energy and momentum, adds a great deal of complexity. Improved atomic-scale computer simulations would be invaluable to more accurately understanding a wide array of real-world applications, especially within the field of nanotechnology.

Now, a team of researchers at Osaka University has developed a new numerical technique to visualize a modeled heat flux at the atomic scale for the first time. “To fundamentally understand thermal transport through a solid–liquid interface, the transport properties of atoms and molecules must be considered,” first author of the study Kunio Fujiwara explains. “We modeled the heat flux near a solid–liquid interface region with sub-atomic spatial resolution by using classical molecular dynamics simulations. This allowed us to create images of the three-dimensional structure of the energy flow while heat was being transferred between the layers.”

Using the popular Lennard–Jones potential to calculate the interactions between adjacent atoms, the team found that the direction of heat flux strongly depends on the sub-atomic stresses in the structures of the solids or liquids.

“Before, there was no good way to visualize heat flux at atomic scale,” senior author Masahiko Shibahara says. “These findings should allow us to elucidate and modify the thermal transport based on the 3D heat flux configuration.”

This may allow for customized nanoscale manufacturing to be carried out more efficiently.

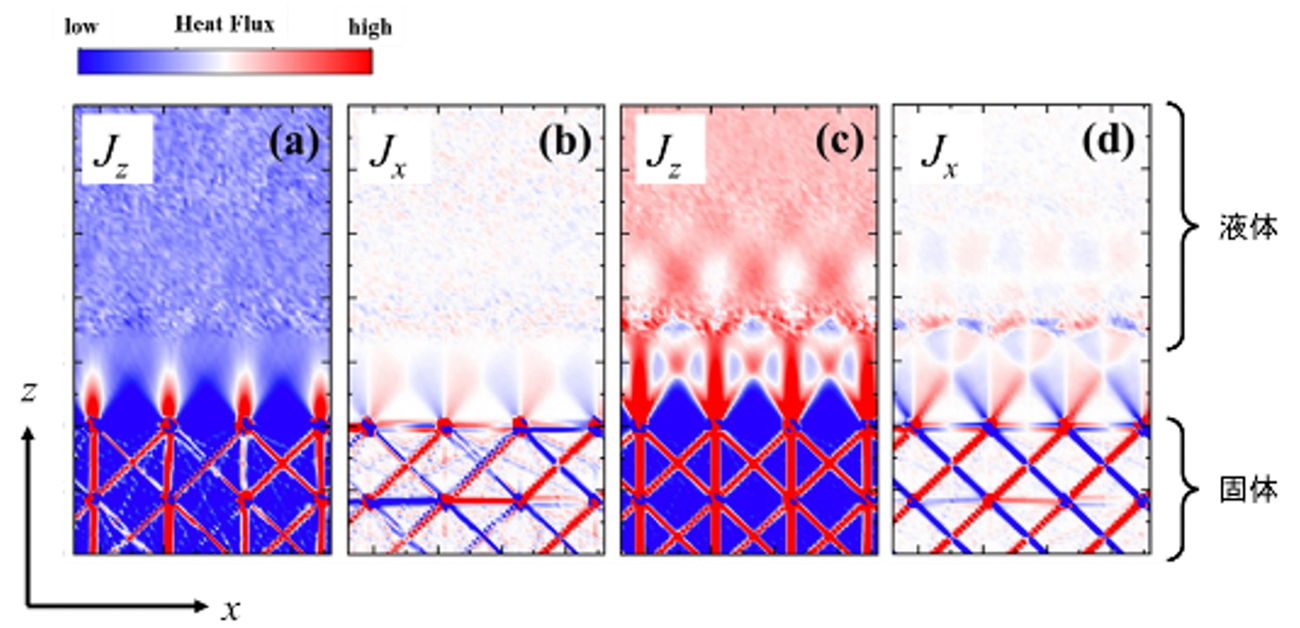

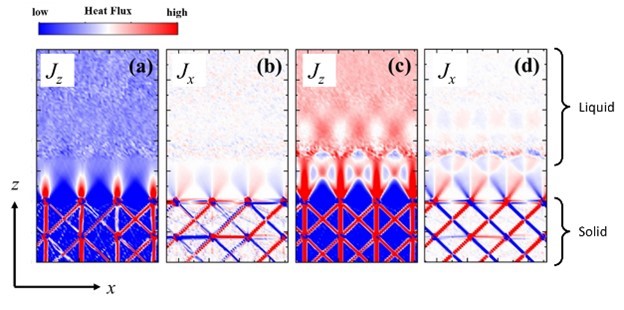

Fig.1 Structure of two-dimensional heat flux at a solid-liquid interface where the temperature gradient is in the z direction, under (a,b) poor or (c,d) good wettability conditions.

*Simulation conditions are different from the results in the paper.

(credit: Kunio Fujiwara and Masahiko Shibahara)

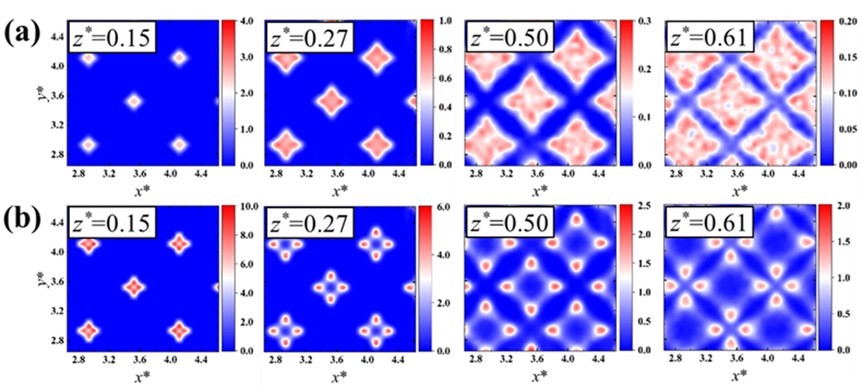

Fig.2 Structure of three-dimensional heat flux at a solid-liquid interface at specified z locations under (a,b) poor or (c,d) good wettability conditions.

*Simulation conditions are different from the results in the paper.

(credit: Kunio Fujiwara and Masahiko Shibahara)

The article, “Thermal transport mechanism at a solid˗liquid interface based on the heat flux detected at a subatomic spatial resolution,” was published in Physical Review E at DOI:

https://doi.org/10.1103/PhysRevE.105.034803.

Related Links

Fujiwara Kunio (Researcher Directory)

EurekAlert!