A small step toward commercialization of ammonia combustion in industrial furnaces instead of fossil fuel

Ammonia combustion technology for reducing NOx generation developed

A group of researchers led by Professor AKAMATSU Fumiteru, Graduate School of Engineering, Osaka University, and Taiyo Nippon Sanso Corporation, have conducted joint research in an effort to use ammonia combustion for industrial furnaces. This joint group succeeded in developing ammonia combustion technology for reducing NOx generation below environmental standards as well as increasing heat transfer from flame. This technology has enabled use of ammonia combustion in industrial furnaces in various fields -- energy consumption in industrial furnaces accounts for about 25% of energy consumption in the whole industrial realm -- and achieved a drastic reduction in CO 2 emissions.

In basic experiments using burners for research tests and numerical calculation methods, the group of researchers from Osaka University clarified the effectiveness of the use of oxygen-enriched combustion in ammonia combustion in terms of increasing flame temperature and reducing NOx generation. This group also demonstrated that heat transfer of ammonia flame is mainly due to radiation by water vapor generated from ammonia combustion.

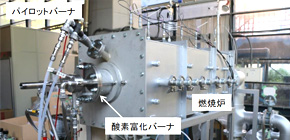

The group of researchers from Taiyo Nippon Sanso Corporation made a burner for oxygen-enriched air designed for single ammonia combustion and methane co-combustion in a 10kW model combustion furnace and clarified characteristics of combustion such as flame temperatures, heat-transfer efficiency, and emission gas compounds.

Oxygen-enriched combustion performed by mixing ammonia as fuel for the burner has the disadvantage that NOx generation increases as the flame temperature rises. This group found that, in order to minimize NOx generation due to increased flame temperatures, combustion technology combining staged combustion with oxygen enriched combustion was effective. In staged combustion, the flame temperature is equalized by taking in atmospheric gas in the furnace in a phased manner.

Based on this technology, using an oxygen enrichment burner in the 10kW model combustion furnace, this group was able to increase flame radiation and drastically reduce concentration of NOx emissions, achieving operation of an industrial furnace using ammonia combustion, which meets current environmental standards.

In order to verify increased flame radiation, this joint group conducted measurements of spatial distribution of the intensity of radiation in ammonia combustion and confirmed that oxygen enriched combustion made it possible to achieve the intensity of radiation in the furnace as a whole, which was more than that of combustion of methane (a major component of natural gas).

This group’s achievement demonstrated the possibility of operation of industrial furnaces without using conventional fossil fuels and drastically reduced CO 2 emission. This group will verify a method for increasing flame radiation in the 10kW model combustion furnace, which is appropriate for practical production in industrial furnaces, and the scaling up of the method for low NOx combustion in order to obtain the prospect of achieving development goals in industrial furnaces. This group also aims to commercialize ammonia combustion technology in industrial furnaces.

Figure 1

Figure 2

Figure 3

Photo 1

Photo 2

Related link