Sharp cracks in rubber are caused by viscoelasticity

Proved the 30-year-old theory proposed by Nobel Prize laureate

- For a long time, it remained unclear why the crack tip becomes sharp when a high-speed fracture occurs.

- The research group is the first to derive the viscoelastic trumpet theory proposed by Dr. Pierre-Gilles de Gennes, a Nobel Prize laureate in Physics, from the basic equations of continuum mechanics, and mathematically demonstrated that sharpening occurs solely due to viscoelasticity, a fundamental property of rubber.

- It is expected to provide a theoretical basis for fracture control and durability improvement of a wide range of polymer materials, from tires to medical materials.

Outlines

As part of the Japan Science and Technology Agency (JST) Strategic Basic Research Programs, a research group consisting of a doctoral student Hokuto Nagatakiya, Assistant Professor Shunsuke Kobayashi, and Professor Ryuichi Tarumi of the Graduate School of Engineering Science at the University of Osaka, and Associate Professor Naoyuki Sakumichi of Faculty of Social Informatics at ZEN University (also serves as Project Associate Professor at the Graduate School of Engineering, The University of Tokyo) has mathematically clarified, for the first time in the world, the mechanism by which crack tips become sharp during high-speed fracture in rubber.

A rubber balloon or a tire burst, due to "high-speed fracture," in which tiny cracks spread in an instant. At this time, the tip of the crack becomes sharp, accelerating the fracture. However, the reason for that phenomenon has not been understood for many years, and the cause was thought to be the complex nonlinear effects of materials.

The research group mathematically and precisely solved the problem of crack propagation and derived a mathematical formula that describes the shape of the crack and the deformation of the entire material. This proved that the sharpening of the crack tip occurs solely due to viscoelasticity that is a fundamental property of polymer materials such as rubber. In addition, the research group mathematically proved the viscoelastic trumpet theory proposed by Dr. Pierre-Gilles de Gennes, a Nobel Prize laureate in Physics approximately 30 years ago, using the fundamental equations of continuum mechanics.

The result of this study provides a theoretical basis for fracture control of a variety of viscoelastic materials, from tires to medical materials, and is expected to contribute to improving product durability, preventing accidents, and reducing environmental burden by making product lifespan longer.

Research Background

Our daily lives are filled with products made from soft, stretchy polymer materials like rubber and gel. Its usages are diverse, including rubber bands, balloons, tires, and medical catheters. These materials are very useful, but they can also fracture in an instant without warning, like snapping of a rubber band, bursting of an inflated balloon or a tire. Such sudden fracture is caused by a tiny crack that appears within the material and quickly propagates throughout the entire material.

Research into how to avoid such sudden fractures has focused on sharpness of the crack tip. When the crack propagation rate is slow, the crack tip has a rounded parabolic profile. However, if the crack propagates extremely fast, the tip will become sharp. It is thought that this sharpening is further accelerating the fracture, leading to the sudden fracture of the material.

However, the fundamental question of "Why does a crack tip become sharper as it progresses faster?" remained unknown. The standard theory, called linear elastic fracture mechanics (LEFM), predicts that the crack tip always has a parabolic profile, and the sharpening phenomenon cannot be explained. Therefore, the established theory is that complex nonlinear effects occur when a material is largely stretched, but this hypothesis alone cannot explain all experimental results. Because the mechanism is unclear, the development of safer and more durable materials has had to rely on trial and error.

Research Contents

In this study, the research group mathematically solved the problem of crack propagation in a viscoelastic solid for the first time in the world and elucidated the mystery of the sharpening of the crack tip.

Conventionally, dynamic fracture problems are extremely complex, and most research has relied on computer simulations that can only handle a limited range of parameters. However, in this study, the researchers developed a new mathematical method to convert dynamic crack propagation into a problem of a stationary crack, solve the converted problem, and then convert it back to the original dynamic crack propagation problem, and successfully derived a mathematical formula indicating the crack shape and the strain distribution inside the material.

The derived formula indicated that the sharpening of the crack tip can be explained solely by viscoelasticity, a basic property of rubber, which is the property of a material that changes state depending on the speed of stretching. If pulled slowly, it will become soft and rubbery; if pulled quickly, it will become viscous and generate heat; and if pulled faster, it will become hard and glassy. In a fast-propagating crack, the tip will become a glassy state, the middle part will become a viscous state, and the far end will become a rubbery state. When the crack propagates faster, the viscous region expands, causing the crack tip to become sharp (Fig. 1). This discovery overturns the conventional theory that "complex nonlinear effects are necessary."

This study clarified the boundaries of the three regions and overall power law exponents that determine the crack shape in each region (Fig. 2).

Surprisingly, the derived exponent was in perfect match with the viscoelastic trumpet theory proposed by Dr. Pierre-Gilles de Gennes, Nobel Prize laureate in Physics, about 30 years ago. He predicted the crack would be a trumpet-like shape based on scaling theory, but his derivation was not mathematically precise, and its relationship to conventional fracture mechanics was unclear. Initially, this study was undertaken with the prediction that it would be possible to disprove the viscoelastic trumpet theory, however, it ultimately indicated that the theory can be precisely derived from the fundamental equations of continuum mechanics, providing a definitive mathematical basis for the 30-year-old theory.

In addition, the research group clarified the strain distribution throughout the material, which was not addressed in Dr. de Gennes' theory, and elucidated that the "plateau region where strain becomes even" in front of a crack observed in recent experiments is caused by viscoelasticity.

The result of this research is groundbreaking because it provides a precise mathematical solution to a complex dynamic fracture problem that could only be handled by numerical calculations, and proves Dr. de Gennes' theory, which was based on physical intuition, from the fundamental equations of continuum mechanics.

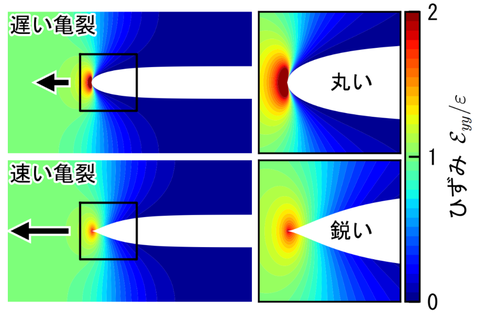

Fig. 1 Changes in crack tip shape and strain distribution due to crack propagation rate

(Upper image) When the crack propagation rate is slow, the crack tip shows a rounded parabolic profile.

(Bottom image) When the crack propagates faster, the viscoelastic effect causes the crack tip to become sharp.

In fracture experiments on rubber and gels, samples with a vertical width of several centimeters to several tens of centimeters are often used. The sharpness of the crack tip is determined by the product of the viscoelastic relaxation time of the material (the time scale for transition from a rubbery state to a viscous-dominated state) and the crack propagation speed (see Fig. 2).

Credit: Ryuichi Tarumi

Fig. 2 Crack surface geometry clarified mathematically

Depending on the distance from the crack tip, the displacement of the crack surface is divided into three regions (glassy region, viscous region, and rubber region) that follow a power law (1/2 power, 3/2 power, and 1/2 power), and the overall shape is like a trumpet. This graph is written as a log-log scale, meaning both axes are logarithmic. On a log-log graph, the first scale corresponds to 10 times, the second scale corresponds to 100 times, and the third scale corresponds to 1000 times, and the exponent of the power law is expressed by the slope of the graph. The position xc of the boundary between the viscous and rubbery regions is determined by the product of the viscoelastic relaxation time of the material and the crack propagation rate and decides the length of the sharp tip. If xc is short, the tip will be parabolic.

Credit: Ryuichi Tarumi

Future Developments

The results of this study have elucidated the role of viscoelasticity in fracture, significantly advancing the understanding of the fracture phenomena of viscoelastic polymer materials. The mathematical formula derived in this study will be a theoretical basis for precise prediction and control of fracture, enabling not only theory-driven material design based on the laws of physics, but also relying solely on the conventional trial-and-error approach. Controlling the process of crack tip sharpening will provide guidelines for designing stronger and safer materials.

Specifically, it is expected to be applied in a variety of fields, such as improving the durability of tires and anti-vibration rubber in the automotive industry and enhancing the safety of medical devices. Longer material lifespan reduces the frequency of product replacement, which also reduces the environmental burden. This study is an important step forward from basic science, contributing to the creation of a safe and secure society and the realization of sustainability.

Notes

The article, “Analytical expression for fracture profile in viscoelastic crack propagation,” was published in Physical Review Research at DOI: 10.1103/4gnw-ys42.