Investigating the Laser-Induced Periodic Surface Structure (LIPSS) of Silicon

Researchers have identified the effects of the choice of laser on LIPSS, providing insight into key manufacturing parameters

The electronic and optical devices that we use on a daily basis, such as mobile phones, LEDs and solar cells use transistors and other constituents that are consistently getting smaller and more compact. With an ever-growing need for computing power, storage, and energy efficiency, this trend will only continue to new extremes. Producing such small components for electronic devices requires the machining and preparation of structures on sub-micron scales, up to hundreds of times smaller than the width of a human hair. But current methods for the nanofabrication of surfaces use photolithography and e-beam lithography— methods that are complicated, extremely expensive, generally inaccessible, and require high levels of expertise. Laser-induced periodic surface structure (LIPSS) has been earmarked as a novel and prospective alternative to these methods. In LIPSS, femtosecond lasers are used to deliver ultrashort laser pulses which spontaneously lead to the formation of periodic patterns on the surface that are much smaller than the laser wavelength.

A well-known parameter in LIPSS is the choice of laser wavelength, which directly affects the periodicity of the formed structures. However other parameters have remained unknown. The major concerns regarding the standardized use of LIPSS include the quality of the formed surface structure, namely in terms of the crystallinity of the substrate and the potential for defects and strain. To consistently produce LIPSS with controllable properties and characteristics for specific applications, it is critical to understand which laser sources should be used for which particular need.

To answer these questions in more depth, a Japanese research collaboration led by scientists from Nagoya Institute of Technology, has now directly investigated the various parameters that are influenced by laser choice. The work, in collaboration with Osaka University, Tokai University, Kyoto University, and the Japan Atomic Energy Agency (JAEA), was led by Assistant Professor Reina Miyagawa of Nagoya Institute of Technology, alongside Associate Professor Norimasa Ozaki of Osaka University, and Professor Masaki Hashida of Tokai University. Their findings have been published in Scientific Reports.

“In our study, we chose silicon as a substrate, as it is a material used in many optoelectronic devices the world over, like transistors, mobile phones and solar cells,” explains Dr. Miyagawa.

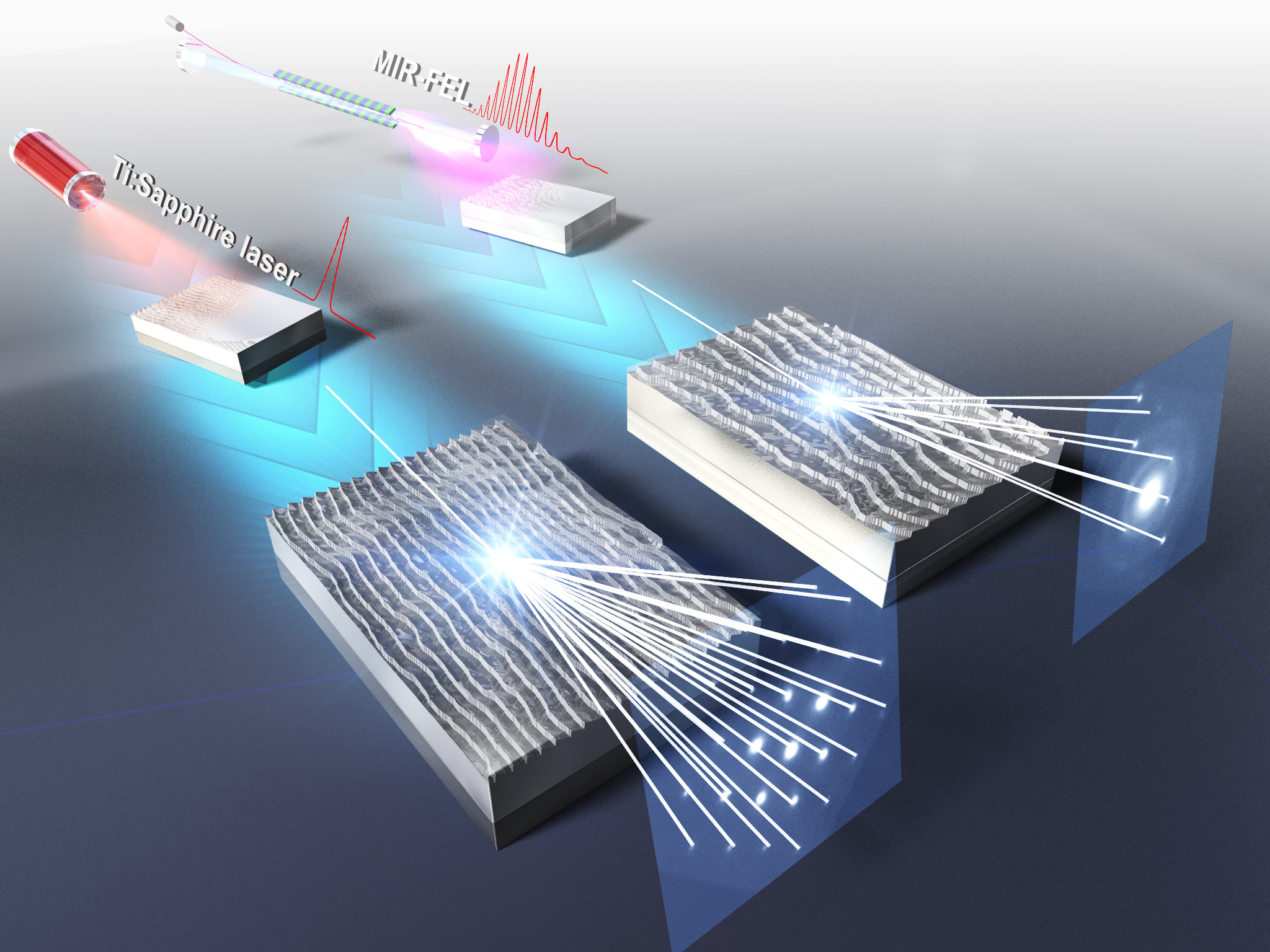

The researchers used two different femtosecond lasers on the substrate. In one experiment, a titanium and sapphire (Ti:Sapphire) laser system with pulses of 0.8 µm was used to structure the silicon at higher than the band-gap energy. In the other experiment, the researchers used a free-electron laser at mid-infrared pulses of 11.4 µm, which could in contrast probe the effect when the energies are lower than the sample band-gap energy. The analysis of the LIPSS samples was done both microscopically and macroscopically. The microscopic crystallinity and purity were studied using transmission electron microscopy (TEM), while a more macroscopic analysis of the strain and stability of the wider structure was investigated using synchotron high-energy X-ray diffraction (XRD).

“When the Ti:Sapphire laser was used, the observed LIPSS retained the highly crystalline nature of the silicon but seemed to take on some residual strain. In contrast, the LIPSS which was formed by the mid-infrared free-electron laser led to some clearly visible defects. However, there was no observable strain to the system whatsoever,” adds Dr. Miyagawa.

This study constitutes the first report on the high-resolution, microscopic and macroscopic observations of crystallinity in LIPSS using synchrotron high-energy x-ray diffraction. The findings indicate how LIPSS can be tuned and tailored for specific applications by manipulating its defects, strain, and periodicity, through an appropriate choice of laser. Continued research along these lines can further open the pathway towards the widespread application of LIPSS to achieve the cost-effective, simple, and accessible fabrication of nanostructured surfaces for applications in a wide range of optoelectronic devices.

Image title: Using lasers with different properties can manipulate LIPSS

Image caption: By using a Ti:Sapphire laser and a mid-infrared free-electron laser (MIR-FEL) to structure silicon, scientists have demonstrated how laser induced periodic surface structure (LIPSS) varies depending on the laser properties

Image credit: Reina Miyagawa of Nagoya Institute of Technology

License type: Original content

Usage restrictions: Cannot be reused without permission

The article, “Crystallinity in periodic nanostructure surface on Si substrates induced by near- and midinfrared femtosecond laser irradiation,” was published in Scientific Reports at DOI: doi.org/10.1038/s41598-022-25365-1

Funding information

This work was supported by Grant-in-Aid for Scientific Research on Innovative Areas Grant Number JP16H06415, Grant-in-Aid for Young Scientists (B) Grant Number JP17K14111, Grant-in-Aid for Challenging Research Pioneering 18H05338, the Amada Foundation Research Grant, MEXT Quantum Leap Flagship Program (MEXT Q-LEAP) Grant No. JPMXS0118070187 and Genesis Research Institute, Inc. (Konpon-ken, Toyota), and ZE Research Program, IAE (ZE2020B-51, ZE2021B-41).

Related Links

Ozaki Norimasa (Researcher Directory)