Staying flexible

Researchers at Osaka University invent a flexible patch containing carbon nanotubes and stretchable conductors that can fit inside a pipe to detect real-time changes in water temperature or the presence of contaminants, which may improve sanitation during industrial processes

Scientists from the Institute of Scientific and Industrial Research (SANKEN) at Osaka University, in collaboration with Chuo University, Eindhoven University of Technology, and National Institute of Advanced Industrial Science and Technology, have developed a non-disruptive sheet sensor for liquid quality monitoring. Using voltages generated in a carbon nanotube layer, the method does not require sampling, chemical labels, or an external light source. The application of this research may enable the on-site quality control of chemical factories or environmentally sensitive water sites.

The monitoring of the chemical content in the water flowing through pipes is critical for industrial applications, such as food or beverage production, as well as for identifying environmental contamination in the effluent that reaches the environment. However, current methods require the periodic collection of samples for testing, as well as the use of chemical reagents or labels. A new approach is needed for non-disruptive continuous monitoring.

Now, a team of researchers has invented a flexible sheet that uses an embedded carbon nanotube film as a photodetector layer. When exposed to light radiation, the carbon nanotubes can produce an electric voltage, which can be detected by attached electrodes. “Our stretchable sheet device is equipped with a high-sensitivity, broadband optical sensor, which enables it to be attached to a wide variety of pipe shapes,” authors Li Kou and Teppei Araki say.

Changes in water temperature could also be monitored passively based on blackbody radiation. For impurity detection or beverage inspection, an external terahertz or infrared light source may be used. This allows spectroscopy methods to be applied continuously to flowing liquids. “The optical sensor sheet can easily visualize the concentration, temperature, viscosity, and location of cracks and liquids in pipes, contributing to the realization of future environmental measurement systems,” say senior authors Yukio Kawano and Tsuyoshi Sekitani. The researchers tested the system and found a linear response between glucose concentration and passively generated voltage.

The team hopes that this research can lead to the modernization of industrial quality control methods, in which contaminant concentrations can be monitored continuously, rather than during scheduled collections.

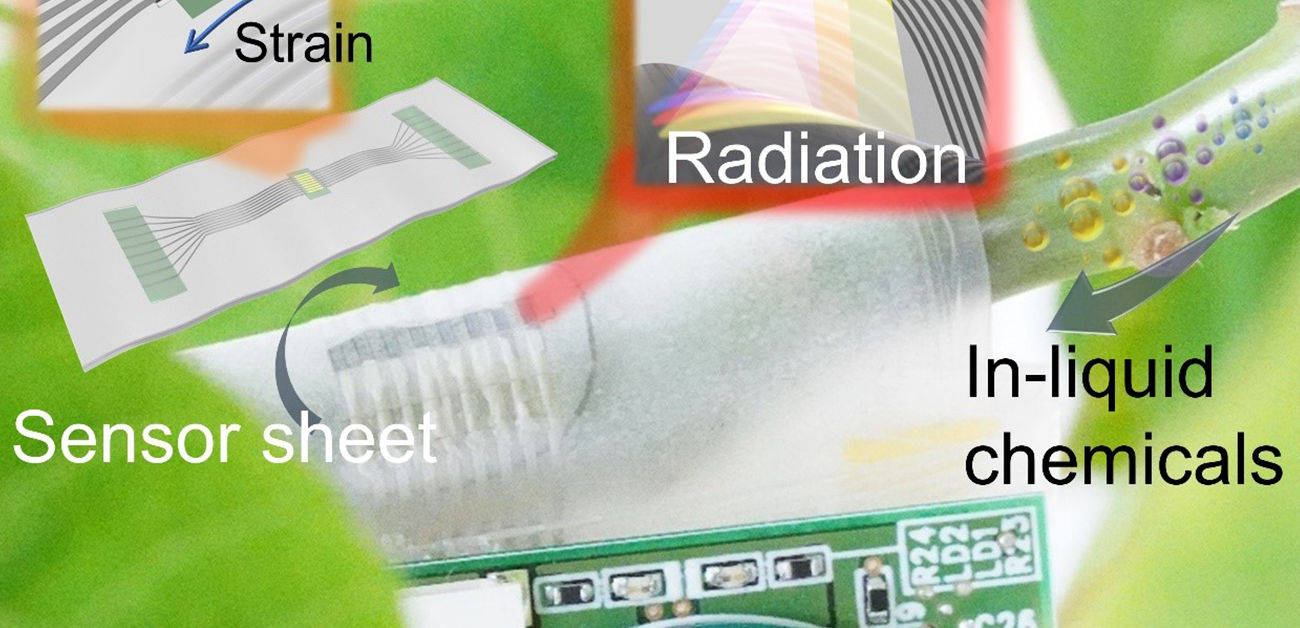

Fig.1 Overview of the research project. The sensor sheet, which fits on a 3-cm square, can be attached to pipes of various sizes and shapes by taking advantage of its elasticity.

(CC BY-NC. 2022 Kou Li et al. Stretchable broadband photo-sensor sheets for nonsampling, source-free, and label-free chemical monitoring by simple deformable wrapping. Science Advances)

Fig.2 Overview and basic performance of the sensor sheet fabricated during this study.

(CC BY-NC. 2022 Kou Li et al. Stretchable broadband photo-sensor sheets for nonsampling, source-free, and label-free chemical monitoring by simple deformable wrapping. Science Advances)

Fig.3 Schematic diagram of a liquid quality measurement. (A-B) Conceptual diagram of the measurement principle. (C-D) Example of a simple aqueous solution concentration measurement. (E-I) Non-disruptive 3D-image reconstruction of shielded liquid flow. (J) Visualization of aqueous solution concentration changes.

(CC BY-NC. 2022 Kou Li et al. Stretchable broadband photo-sensor sheets for nonsampling, source-free, and label-free chemical monitoring by simple deformable wrapping. Science Advances)

The article, “Stretchable broadband photo-sensor sheets for nonsampling, source-free, and label-free chemical monitoring by simple deformable wrapping” was published in Science Advances at DOI: https://doi.org/10.1126/sciadv.abm4349.