AI technologies enabling robotic assembly lines for production of diversified products

A group of researchers from the New Energy and Industrial Technology Development Organization (NEDO), the National Institute of Advanced Industrial Science and Technology (AIST), Osaka University, and Chubu University developed Artificial Intelligence (AI) technologies to realize autonomous part supply and assembly by robots on the shop floor.

To meet increasingly diversified consumer demands, robot-assisted manufacturing systems capable of doing complicated work cell operations are required. Robots could be used throughout the process from part supply to assembly of parts. Thus, after the introduction of robots, it is necessary to improve the efficiency of robot operation in part supply and assembly of parts and reduce the time for preparing work plans using information from robot vision sensors.

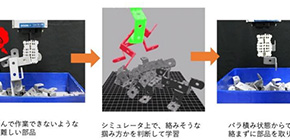

The technologies the team developed allow a robot to learn on a computer simulation so that it can learn operations without depending on the actual machine and to copy demonstrations given by assemblers on the shop floor so that the robot can learn and perform the operation on the spot. In addition, they developed an efficient compression and reconstruction technique using matrix decomposition of image data of a robot hand with vision sensors, reducing the computation time for detecting grasping positions.

The following software for introducing industrial robots was released to the public on a special website on August 29, 2019. ( https://nedo-robot-ai.jimdofree.com/ )

- Simulation software for bin picking

- Software to make work instructions to allow a robot to assemble parts by replicating assembly operations by a person

- Software to quickly detect a robot’s grasping positions using the robot’s vision sensors

This group hopes that sharing their technologies with companies and research institutes interested in the introduction of industrial robots will lead to trial use in assembly lines and R&D applications through joint R&D in the future.

Their technologies allow for (a) advance planning of part supply and assembly by robots through scanning the shape of parts to pick and learning manipulation behaviors from observing the motion executed by human demonstrators and (b) efficient planning by reducing the time for robot programming using data from vision sensors. These technologies will promote the incorporation of robots into assembly lines for limited production of diversified products that require complex-shaped parts, enhancing productivity in the manufacturing industry.

Figure 1

Figure 2

Figure 3

Related links