Successful low temperature growth of high-quality metal oxide nanowires

Will lead to application to solar cells and lithium-ion batteries

A group of researchers at The Institute of Scientific and Industrial Research, Osaka University and the Institute for Materials Chemistry and Engineering, Kyushu University developed a method for reducing the growth temperature in a vapor-liquid-solid (VLS) process of metal oxide nanowires.

Metal oxide nanowires are materials of interest in a number of applications such as solar cells, lithium-ion batteries, supercapacitors, and non-volatile memory. Thus, a method to synthesize high-quality nanowires by controlling their size and position is required.

The VLS growth method enables the synthesis of various high-quality functional inorganic materials. In this method, it is also possible to tailor the diameter and spatial position of nanowires by adjusting the size and spatial position of metal nanoparticles, which become the nuclei for the growth. These excellent features are hardly attainable by other nanowire growth methods including hydrothermal nanowire synthesis. However, synthesis of metal oxide nanowires using the VLS growth method required high temperatures (600 - 1000˚C). In order to synthesize nanowires on thermally unstable substrates, reducing the growth temperature was necessary.

This group succeeded in synthesis of metal oxide nanowires at a low temperature of 400˚C or lower by precisely controlling the material flux. They discovered conditions for low temperature growth of metal oxide nanowires by examining products when the material flux and growth temperatures were systematically changed in the VLS nanowire growth of metal oxides.

This method has made it possible to grow high-quality nanowires of various metal oxide on unstable substrates. It is anticipated that this method will expand the scope of application of metal oxide nanowires.

Abstract

Vapor–liquid–solid (VLS) growth process of single crystalline metal oxide nanowires has proven the excellent ability to tailor the nanostructures. However, the VLS process of metal oxides in general requires relatively high growth temperatures, which essentially limits the application range. Here we propose a rational concept to reduce the growth temperature in VLS growth process of various metal oxide nanowires. Molecular dynamics (MD) simulation theoretically predicts that it is possible to reduce the growth temperature in VLS process of metal oxide nanowires by precisely controlling the vapor flux. This concept is based on the temperature dependent “material flux window” that the appropriate vapor flux for VLS process of nanowire growth decreases with decreasing the growth temperature. Experimentally, we found the applicability of this concept for reducing the growth temperature of VLS processes for various metal oxides including MgO, SnO 2 , and ZnO. In addition, we show the successful applications of this concept to VLS nanowire growths of metal oxides onto tin-doped indium oxide (ITO) glass and polyimide (PI) substrates, which require relatively low growth temperatures.

Figure 1. Schematic of a rational concept to reduce the growth temperature in VLS process of metal oxide nanowires.

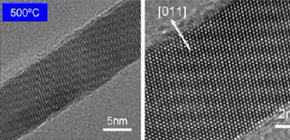

Figure 2. (a) Scanning electron microscopy images of SnO2 nanowires formed via a VLS process when varying the growth temperature and the Sn metal vapor flux. (b) High resolution transmission electron microscopy images of a SnO2 nanowire.

To learn more about this research, please view the full research report entitled " Rational Concept for Reducing Growth Temperature in Vapor−Liquid−Solid Process of Metal Oxide Nanowires " at this page of the Nano Letters website.

Related link