Successful development of high-polymer materials with high charge mobility

Obtaining ideal charge mobility in π-conjugated polymer chains within reach?

Under the leadership of TERAO Jun , Associate Professor, and TSUJI Yasushi , Professor, Graduate School of Engineering, Kyoto University; TADA Tomofumi , Associate Professor, TokyoTech Material Research Center for Element Strategy, Tokyo Institute of Technology; and SEKI Shu , Professor, Graduate School of Engineering, Osaka University , a group of researchers succeeded in developing high-polymer materials with high charge mobility by substituting zigzag wires for linear wires in π-conjugated chains.

Inorganic semiconductor materials such as silicon are still major players in the fabrication of electronic devices in our modern information society. On the other hand, organic semiconductor materials mainly made of carbon π-conjugated polymers, known as plastics that conduct electricity, have drawn attention because of their advantage in being more suitable than low-molecular organic compounds are. Printing technology such as inkjet printing and rotary press can be used in their fabrication, so π-conjugated polymers are expected to reduce production cost.

However, their charge mobilities, a parameter for carrier transport property, have not been comparable to those of silicon-based inorganic semiconductor materials. This is the biggest challenge in developing high-polymer materials for semiconductors and the development of such materials with high charge mobility is being eagerly awaited.

To achieve more effective charge mobilities in polymer chain, this group tried to achieve efficient charge hopping by regularly localyzing polymer molecular orbitals to achieve an ideal orbital alignment, and at the same time, by equalizing energy strength and making use of thermal energy.

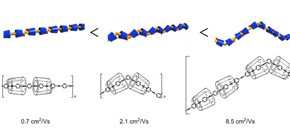

This group designed and synthesized insulated wires containing meta-junctioned poly (phenylene–ethynylene) as backbone units. The zigzag wires exhibited higher intramolecular charge mobility than the corresponding linear wires. This group's achievement demonstrated that covering the main chain of π-conjugated polymers with a dense coat and using regularly localized molecular orbitals are effective for increasing charge mobility of π-conjugated polymers.

The application of this technology to π-conjugated polymer backbones will lead to the possible creation of π-conjugated polymers with higher charge exchange. Insulated π-conjugated polymers are expected to be used as organic semiconductor materials and wires in molecular devices.

Figure 1

Abstract

The feasibility of using π-conjugated polymers as next-generation electronic materials is extensively studied; however, their charge mobilities are lower than those of inorganic materials. Here we demonstrate a new design principle for increasing the intramolecular charge mobility of π-conjugated polymers by covering the π-conjugated chain with macrocycles and regularly localizing π-molecular orbitals to realize an ideal orbital alignment for charge hopping. Based on theoretical predictions, insulated wires containing meta-junctioned poly(phenylene–ethynylene) as the backbone units were designed and synthesized. The zigzag wires exhibited higher intramolecular charge mobility than the corresponding linear wires. When the length of the linear region of the zigzag wires was increased to 10 phenylene–ethynylene units, the intramolecular charge mobility increased to 8.5 cm 2 V −1 s −1 . Theoretical analysis confirmed that this design principle is suitable for obtaining ideal charge mobilities in π-conjugated polymer chains and that it provides the most effective pathways for inter-site hopping processes.

To learn more about this research, please read the full research report entitled " Design principle for increasing charge mobility of π-conjugated polymers using regularly localized molecular orbitals " at this page of the Nature Communications website.

Related links :