Corrosion-resistant non-noble metal electrodes in acidic electrolytes developed

Practical electrode performance achieved at a low cost

A group of researchers from the University of Tsukuba and Osaka University developed a non-noble electrode which does not get damaged when used in acidic electrolytes.

Hydrogen is anticipated as a next-generation source of renewable energy. Through combination with natural energy such as water, wind, and solar power, hydrogen can generate clean electricity with no exhaust gas. The establishment of hydrogen generation methods using energy other than fossil fuel power that are both efficient and environmentally-friendly are highly sought after.

Noble metals such as platinum (Pt) are used in electrodes for hydrogen generation systems; however, non-noble metal electrodes have been sought after as an alternative to expensive and scarce Pt. Non-noble metals are excellent in terms of cost and performance in hydrogen evolution reactions (HER), but are also corrosive when used in acidic electrolytes, so it was difficult to prevent corrosion while maintaining electrode performance.

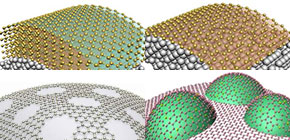

The researchers explored conditions for developing corrosion-resistant non-noble metal electrodes for electrochemical water splitting in acidic electrolytes, fabricating non-noble metal electrodes covered with graphene layers. Supporting nickel-molybdenum (NiMo) nanoparticles on porous graphene layers, they grew one to ten graphene layers using a chemical vapor deposition (CVD) method. In addition, by changing conditions for the CVD method, they fabricated 1-2, 2-3, 3-5, and 10 graphene layers on the surface of NiMo nanoparticles.

Using these NiMo nanoparticles/porous graphene covered with different numbers of graphene layers as electrodes (cathode), the researchers conducted hydrogen generation experiments in strong acidic electrolytes (0.5M sulfuric acid aqueous solution). As a result, it was suggested that the number of graphene layers determined corrosion of non-noble metals and electrode performance. This has provided guidelines for securing both non-noble metal electrode lifetime and HER performance in acidic electrolytes.

In this study, it was possible to protect non-noble electrodes from corrosion and ensure electrode performance in acidic electrolytes by covering the surface of NiMo nanoparticles porous alloy with thin graphene layers of 3–5 carbon atoms. In addition, a current density of 0.2 A/cm 2 (necessary for practical use of electrolysis of water) was maintained for a week, a world first.

The production cost of this corrosion-resistant non-noble metal electrode is 1/100th that of a platinum electrode and has a longer lifetime than conventional ones, so it will be used as an electrode for electrolysis of water.

Abstract

Acid-stable, non-noble catalysts are promising for hydrogen evolution reaction (HER); however, they get easily damaged when used in acidic electrolytes, thus reducing the HER lifetimes. Moreover, completely blocking catalysts from acidic electrolytes degrades HER performance. To achieve a balance between the HER lifetime and performance, we vary the number of N-doped graphene layers (1–2, 2–3, and 3–5 layers) encapsulating NiMo nanoparticles as efficient HER catalysts and obtain the optimal number of protective layers. Our data show that 3–5 graphene layers achieved the best balance, with a stable current density of 100 mA cm –2 for 25 h in 0.5 M H 2 SO 4 . Density functional theory calculations are performed to show the effect of encapsulating graphene layer number on the catalytic activity and protection of non-noble NiMo in acidic electrolytes.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

The article, "Graphene Layer Encapsulation of Non-Noble Metal Nanoparticles as Acid-Stable Hydrogen Evolution Catalysts," was published in ACS Energy Letters , https://doi.org/10.1021/acsenergylett.8b00739 .

Related link