Development of a technique enabling fluorine-containing resin to adhere strongly to a metal film

With this technique a roughened fluorine-containing resin surface is no longer required.

Likely used in: energy-saving, high frequency printed circuit boards (PCBs) for high-speed processing units

A joint group of researchers at Osaka University and the Advanced Technology Research Laboratory of NOF CORPORATION has developed a technique enabling metal to adhere strongly to the surface of a flat fluorine-containing resin (Patent pending). That is, with this technique a roughened fluorine-containing resin surface is no longer required.

Osaka University staff involved in this project : YAMAMURA Kazuya (Associate Professor), OHKUBO Yuji (Assistant Professor), SATO Haruka (1st-year student in the first-term of a doctoral program) -- Ultra-Precision Science & Technology, Graduate School of Engineering.

Efforts have been made to increase CPU speed by increasing the operating frequency in electronic devices such as mobile phones and communication circuits. However, an increase in operating frequency causes technological problems such as a decrease in signal speed and an increase in power consumption. In order to solve these problems, materials for PCBs are being examined. The good dielectric properties of resin materials for PCB fabrication substantially minimize the problems of signal speed and power consumption.

The dielectric property of polytetrafluoroethylene (PTFE), known by the trade name of Teflon®, is superior to that of all other PCB materials and is, therefore, expected to be a prospective material for high frequency PCBs. However, PTFE has the highest water-repellent and oil-repellent properties of all types of fluorine-containing resins and, therefore, it’s hard to make it stick to other materials. A sodium-naphthalene complex solution is capable of enhancing the adhesion strength of a fluorine-containing resin; however, a roughened surface is needed for improving the adhesion strength in this case, and doing so, worsens the electric flow. Therefore, it can be seen that a technology for improving adhesion between metal and a flat, smooth resin substrate is required.

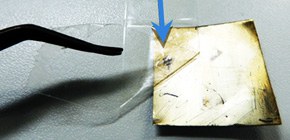

The Osaka University and NOF CORPORATION group, by making use of a PTFE surface functional coating with an atmospheric-pressure plasma and surface graft polymerization with low temperature solidified silver ink, succeeded in achieving strong adhesion between a metal and a smooth resin substrate.

This technology achieved strong adhesion between a metallic film and the surface of fluorine-containing resin substrate which had not been roughened, enhancing the feasibility of using the fluorine-containing resin as a material for high frequency PCBs. By making use of drop-on-demand feeding technique using silver ink, electric circuits can be formed on fluorine-containing resin. A metal film is prepared by only applying silver ink and low-temperature heating, so the processing is easy and liquid waste disposal is not required. This will lead to the production of environmentally friendly high frequency PCBs. This joint group's technique for adhering a metal film to fluorine-containing resin will contribute to increased applications for fluorine-containing resin.

Images

Link