Hitting the bull’s-eye with 3D nanofabrication

Satoshi KAWATA, Professor, Department of Applied Physics

Next-generation lithography uses laser drawing technology to build incredibly small objects from the bottom up

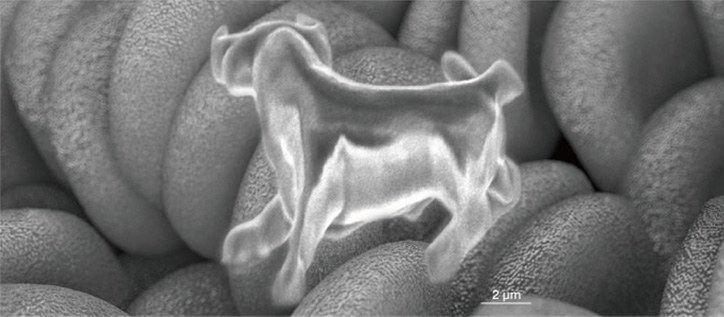

Credit:2013 by WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (foreground)

© royaltystockphoto/iStock/Thinkstock (background)

Caption:A tiny sculpture of a bull no larger than a red blood cell (background) created in 2001 set the stage for 15 years of advances in three-dimensional nanofabrication.

Hitting the bull’s-eye with 3D nanofabrication

Next-generation lithography uses laser drawing technology to build incredibly small objects from the bottom up

In 2001, Satoshi Kawata from Osaka University stunned the science world when he and his team used a laser beam to sculpt a three-dimensional (3D) bull, no larger than a red blood cell, from a polymer resin (see image). Kawata’s ‘two-photon’ laser technique brought pinpoint 3D construction to the nanoscale realm for applications such as biocompatible scaffolds and light-driven motors.

“When we started this project, I was very frustrated with nanotechnology,” recalls Kawata from his bustling Osaka laboratory in the Department of Applied Physics. Although 3D printers have earned recent fame for creating real objects using computer-aided scanners and photocurable polymers, similar technologies did not exist for nanoscale fabrication at that time. “Etching and modifying silicon surfaces was fine for two-dimensional patterning, but for applications such as nanomachines or nanocircuits we had to find a way to produce 3D objects. We knew this was the future.”

Kawata’s nanofabrication strategy relies on two key features. Near-infrared femtosecond lasers are used to generate pulses that penetrate deeply into materials to process 3D structures. The resolutions of traditional laser prototyping machines are limited by the wavelength of light, whereas the two-photon laser technique uses nonlinear interactions between photons and materials to control light spots as small as 100 nanometers in three independent directions.

Furthermore, the nanofabrication strategy requires using special polymers containing dyes that respond to two-photon excitation. Kawata and colleagues have pioneered ways to combine these elements into a nano drawing system that rapidly carves shapes from solid objects, as opposed to slow, layer-by-layer 3D printing.

Zouheir Sekkat, a professor at Osaka University and at the Mohammed V University in Morocco, has teamed up with Kawata in a recent review article to assess 15 years of laser nanofabrication since the miniature bull1. The duo note that the development of photosensitive materials remains one of the primary challenges in this field, but success can potentially lead to high rewards. For example, 3D structures made from azopolymers — compounds bearing azobenzene molecules that can be switched between two geometries by light stimulation — may form the basis of novel molecular machines such as nanoscale cantilevers that bend in response to light.

The researchers also examine how two-photon techniques can turn non-polymeric materials, namely metals, into springs, gears and ‘metamaterials’ — complex periodic assemblies that manipulate electromagnetic waves for applications such as microscale antennas and cloaking devices. “Producing metamaterials is usually difficult with standard two-dimensional lithography,” says Kawata, “but two-photon photoreduction of metals solves this problem.”

Related link

Professor Satoshi Kawata

Department of Applied Physics

Osaka University

kawata@ap.eng.osaka-u.ac.jp

Reference:

1.Sekkat, Z. & Kawata, S. Laser nanofabrication in photoresists and azopolymers. Laser & Photonic Reviews 8, 1–26 (2014).

This research project was supported by the Osaka University International Joint Research Promotion Program, which aims to further enhance research quality and promote globalization at Osaka University through advanced research with overseas collaborators. Professor Kawata jointly conducted this research with the following researchers: Professor Zouheir Sekkat, Moroccan Foundation for Advanced Science, Innovation and Research, Morocco (Professor Sekkat is also a professor at Osaka University by the Osaka University´s Cross-Appointment System.)

Interview held in March 2016