The mechanism of structural rejuvenation of metallic glass theoretically elucidated

Graduate School of Engineering Science, Osaka University -- WAKEDA Masato (Assistant Professor), OGATA Shigenobu (Professor)

Frontier Research Institute for Interdisciplinary Sciences, Tohoku University -- SAIDA Junji (Professor)

Massachusetts Institute of Technology, U.S. -- Ju Li (Professor)

A group of researchers from Osaka University, Tohoku University, and Massachusetts Institute of Technology succeeded in theoretically clarifying the "structural rejuvenation" of metallic glass via thermal processing at low temperatures and quenching. Structural rejuvenation recovers and controls the relaxation state of metallic glass. This group's achievements will avoid embrittlement phenomena, a concern for casting and processing of metallic glass, and make it possible to increase and stabilize practical characteristics of metallic glass, leading to its usage in small electronic devices such as smartphones.

Abstract

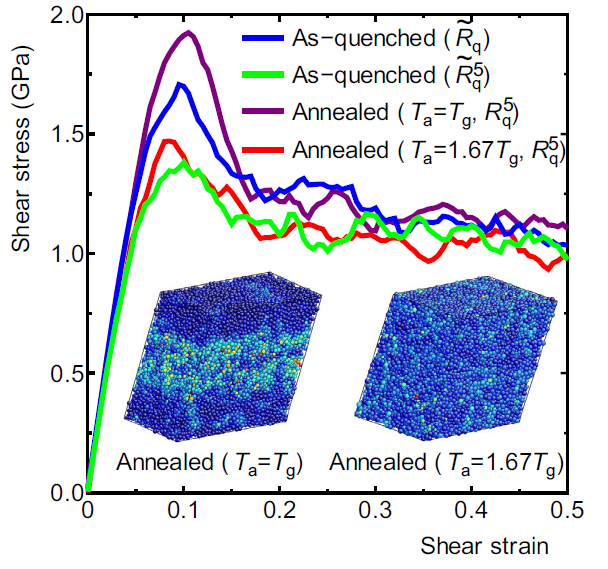

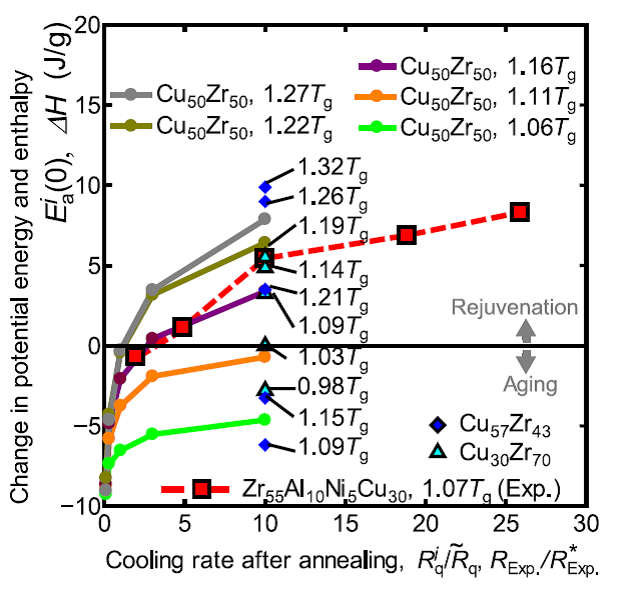

Rejuvenation is the configurational excitation of amorphous materials and is one of the more promising approaches for improving the deformability of amorphous metals that usually exhibit macroscopic brittle fracture modes. Here, we propose a method to control the level of rejuvenation through systematic thermal processing and clarify the crucial feasibility conditions by means of molecular dynamics simulations of annealing and quenching. We also experimentally demonstrate rejuvenation level control in Zr55Al10Ni5Cu30 bulk metallic glass. Our local heat-treatment recipe (rising temperature above 1.1Tg, followed by a temperature quench rate exceeding the previous) opens avenue to modifying the glass properties after it has been cast and processed into near component shape, where a higher local cooling rate may be afforded by for example transient laser heating, adding spatial control and great flexibility to the processing.

Figure 1. Change in deformation properties of metallic glass by rejuvenation: the right model with rejuvenated structure shows more homogenous deformation mode.

Figure 2. Conditions of heating temperature and cooling rate required for thermal rejuvenation: higher heating temperature and higher cooling rate realize higher rejuvenated state.

To learn more about this research, please view the full research report entitled " Controlled Rejuvenation of Amorphous Metals with Thermal Processing " at this page of the Scientific Reports website.

Related link