Silk fibers improve bioink for 3D-printed artificial tissues and organs

Researchers from Osaka University mechanically reprocess silk into a biologically compatible component of bioinks that improves the structural fidelity of 3D-printed hydrogels containing cells for use in drug development and regrowing lost or damaged body parts

How do you test, in early-stage research, whether a potential pharmaceutical effectively targets a human tumor, organ, or some other part of the body? How do you grow a new hand or some other body part? Researchers are in the early stages of using 3D cell printing technology to make developments like these happen. A standard way—currently unavailable—to fix the cells in place after printing would help researchers avoid having to ‘reinvent the wheel’ in every new investigation.

In a study recently published in Materials Today Bio , researchers from Osaka University have used silk nanofibers obtained by mechanical disintegration to enhance the printing process without damaging the cells or cell assemblies. An attractive point of silk for this application is that silk is believed to be a safe material for humans. This development will help bring 3D cell printing research out of the laboratory and into real-world biomedical use.

To obtain the fibers, the researchers started with virgin silk, then removed the protein sericin from it because this protein causes inflammation in patients. Next, the researchers ground the remaining biocompatible material into nanofibers. The fibers can be sterilized—without damaging them—for medical use, with common laboratory equipment.

"Our silk fibers are excellent additives to bioink cell printing media," says lead author Shinji Sakai. "They are compatible with many media, such as those containing gelatin, chitosan, or hyaluronic acid, giving them a broad range of potential applications."

The main purpose of the fibers was to ensure that the cells in the bioink retained their 3D positioning after printing without damaging the cells. The fibers fulfill this purpose by enhancing the integrity of the bioink and minimizing the damaging high mechanical stresses often placed on cells during printing.

"Various mechanical experiments say the same thing: the nanofibers enhanced the properties of the printing media," explains Professor Sakai. "For example, Young's modulus—a measure of stiffness—increased several-fold and remained enhanced for over a month."

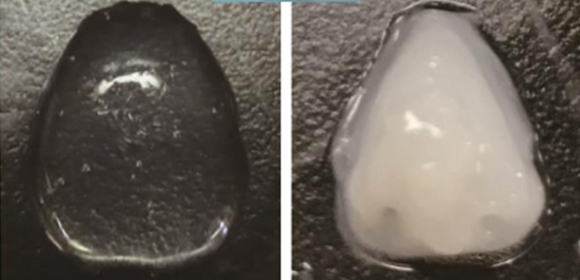

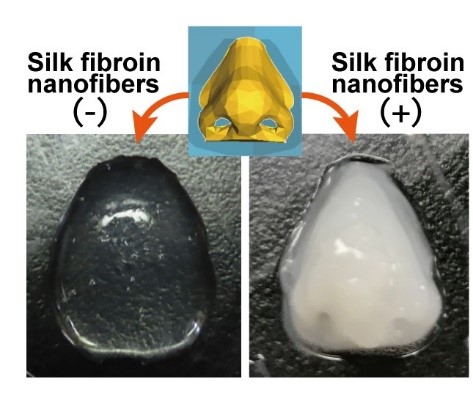

The fibers help printed configurations retain their structural integrity after printing. For example, a nose-shaped configuration retained its shape only when printed with bioink containing the silk fibers. Over 85% of the cells in the bioink remained alive after a week in the printed bioink with or without the added fibers, indicating that adding the fibers did not damage the cells.

Current cell printing technology often heavily damages cells or does not retain the intended shape for long. The research here helps overcome these limitations in a way that will help advance drug discovery, regenerative medicine, and many other ongoing high-impact biomedical research fields, and has the potential added economic benefit of reinvigorating the silk industry.

Figure. 3D printed constructs using hyaluronic acid-based inks free of silk fibroin nanofibers (-) and containing silk fibroin nanofibers (+).

The article, "Silk fibroin nanofibers: A promising ink additive for extrusion 3D bioprinting," was published in Materials Today Bio at DOI: https://doi.org/10.1016/j.mtbio.2020.100078 .

Related Links