Solidification and transformation in Fe–C alloys clarified by X-ray imaging

Will serve as guidelines for improving productivity and properties of ferrous materials

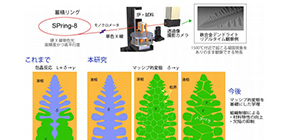

A group of researchers from Kyoto University, in cooperation with Osaka University, Osaka Sangyo University, and the Japan Synchrotron Radiation Research Institute (JASRI), using X-ray imaging at the large synchrotron radiation facility SPring-8, demonstrated that a massive-like transformation from body-centered cubic (BCC) structure to a face-centered cubic (FCC) structure occurred during or after ferrite solidification in iron-carbon (Fe–C) alloys and that this transformation induced dendrite arm fragmentation under appropriate temperature conditions. Dendrite is a tree-like structure of crystals growing as molten metal solidifies.

Carbon steel primarily comprised of iron (Fe) and carbon (C) is one of the important materials of social infrastructure and the improvement of its productivity and mechanical properties will affect society as a whole. Most carbon steel is produced through a solidification casting process to solidify liquid steel.

Previously, in Fe–C alloys with carbon contents < 0.5 mass%, the γ phase (austenite, FCC) was thought to be produced through a peritectic reaction between the δ phase (ferrite, BCC) and the liquid phase.

Carbon steel is the most important commercial steel alloy. Increasing carbon content increases hardness and strength. Austenite-ferrite transformation is used for controlling properties of carbon steel. Since it was difficult to perform nanoscale observation of carbon steel whose melting point is 1500℃, some issues remained unsolved.

This group developed a method to observe the solidification processes of carbon steel using synchrotron radiation to clarify solidification of high temperature materials. They also reported that massive-like transformation from ferrite to austenite occurred in carbon steel and stainless steel.

In this study, they clarified:

- 1. A peritestic reaction does not occur in the solidification process, but a massive-like transformation from ferrite to austenite produces refined austenite grains.

- 2. Dendrite fragmentation is induced by the melting at the γ grain boundary and the δ–γ interface under appropriate temperature conditions.

Dendrite arm fragmentation through a massive-like transformation can be used for texture control of materials. It may also be related to casting defects generated in the solidification process. Moving forward, the researchers will continue their research in order to connect their discovery with the production process of materials and the improvement of their properties.

Figure 1

The article “Dendrite fragmentation induced by massive-like δ–γ transformation in Fe–C alloys” was published in Nature Communications at DOI: https://doi.org/10.1038/s41467-019-11079-y .

Related links