High-performance anode material for lithium-ion batteries (LIBs) produced from waste Si sawdust

Will lead to high-performance of batteries for smartphones

A group of researchers led by Associate Professor NISHIHARA Hirotomo and Professor KYOTANI Takashi at the Institute of Multidisciplinary Research for Advanced Materials, Tohoku University, and Associate Professor MATSUMOTO Taketoshi and Professor KOBAYASHI Hikaru at The Institute of Scientific and Industrial Research, developed a method for recycling waste silicon (Si) sawdust as high-performance anode material for lithium-ion batteries (LIBs).

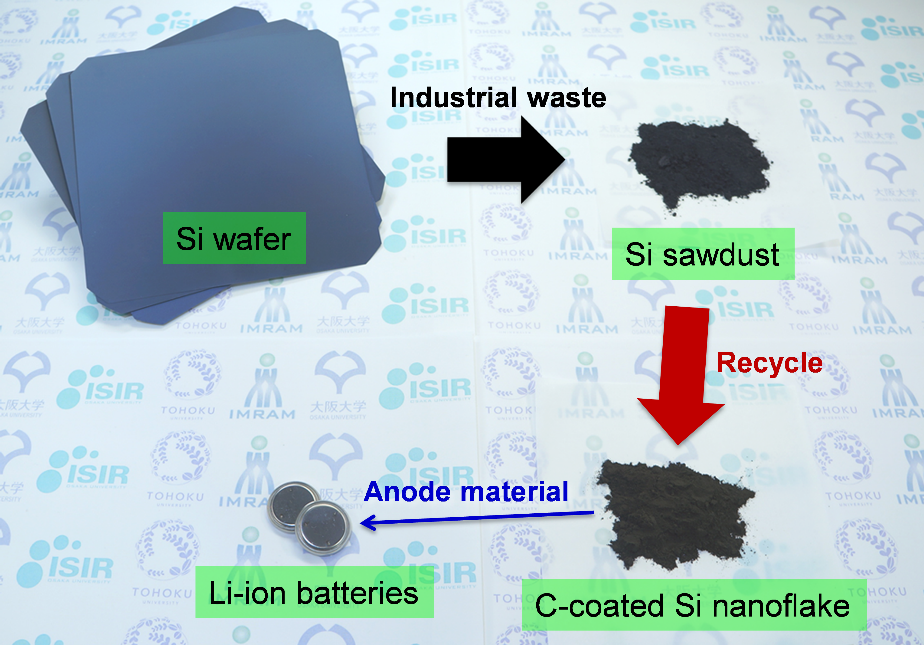

A large amount of Si wafer is produced for semiconductors and solar batteries; however, some 50% of Si is discarded as industrial waste.

This group found that if Si sawdust were converted into nanoflakes with a very thin thickness, the Si sawdust could be used as a long-life high-capacity anode material for LIBs. It was also found that Si nanoflakes increased their performance and lifespan through carbon-coating and that under the restriction of the lithiation capacity up to 1200 mAh g −1 , or some 3.3 times that of graphite used for a conventional LIBs, a constant capacity could be retained over 800 charge/discharge cycles.

Since the amount of Si sawdust generated worldwide exceeds the demand in materials for the anode material for LIBs in the world, Si sawdust is an ideal resource. In this method, industrial waste is used. In addition, a simple and easy method is employed for converting Si sawdust into nanoflakes as well as carbon-coating, which can handle a large amount of silicon. This group’s achievements will lead to the recycling of Si sawdust as a high-performance anode material for LIBs.

Abstract

Nowadays, ca. 176,640 tons/year of silicon (Si) (>4N) is manufactured for Si wafers used for semiconductor industry. The production of the highly pure Si wafers inevitably includes very high-temperature steps at 1400–2000 °C, which is energy-consuming and environmentally unfriendly. Inefficiently, ca. 45–55% of such costly Si is lost simply as sawdust in the cutting process. In this work, we develop a cost-effective way to recycle Si sawdust as a high-performance anode material for lithium-ion batteries. By a beads-milling process, nanoflakes with extremely small thickness (15–17 nm) and large diameter (0.2–1 μm) are obtained. The nanoflake framework is transformed into a high-performance porous structure, named wrinkled structure, through a self-organization induced by lithiation/delithiation cycling. Under capacity restriction up to 1200 mAh g −1 , the best sample can retain the constant capacity over 800 cycles with a reasonably high coulombic efficiency (98–99.8%).

Fig. Production process from silicon wafer to lithium battery anode.

To learn more about this research, please view the full research report entitled “ Beads-Milling of Waste Si Sawdust into High-Performance Nanoflakes for Lithium-Ion Batteries ” at this page of the Scientific Reports website .

Related links