A technique enabling fluorine-containing resin to adhere strongly to a metal film without using adhesive

Joint development by Osaka University, Sekisui Chemical Co., Ltd. and NOF Corporation will accelerate practical use

A joint group of researchers from Osaka University, Sekisui Chemical Co., Ltd. R&D Center, and the Advanced Technology Research Laboratory of NOF Corporation are going to put a technique enabling metal to adhere strongly to the surface of a flat fluorine-containing resin into practical use.

Research Center for Ultra-Precision Science and Technology, Graduate School of Engineering, Osaka University -- YAMAMURA Kazuya (Associate Professor), OHKUBO Yuji (Assistant Professor)

Because of its water-repellent and oil-repellent properties, fluorine-containing resin is widely used in products for daily use such as water-repellent coats and non-stick frying pans with coating. Fluorine-containing resin also has an excellent electric property, so it is expected to be used in materials for high frequency PCBs to respond to an increased amount of information communication. However, as fluorine-containing resin is chemically inactive, it is very difficult to make it stick to other materials.

In response to this, Osaka University, in cooperation with other research institutes, has developed a technique enabling metal and butyl rubber to adhere strongly to the surface of a flat fluorine-containing resin by irradiating atmospheric-pressure plasma to fluorine contained resin (Patent application: 2014-181663). In order to accelerate its practical use and dissemination, Osaka University, Sekisui Chemical Co., Ltd. and NOF Corporation have decided to jointly perform technological development.

This technology will make it possible to produce high frequency PCBs using fluorine-contained resin at a low cost. It will contribute to the spreading of millimeter-wave radar for anticollision systems for vehicles as well as the rapid processing of large amounts of information communication. It will also expand the application of metals coated with fluorine-containing resin.

This group's achievements will be presented at the SURTECH2016 to be held at Tokyo Big Sight from January 27 through January 29, 2016 and the 133rd Conference of the Surface Finishing Society of Japan at Waseda University to be held from March 22 through March 23, 2016.

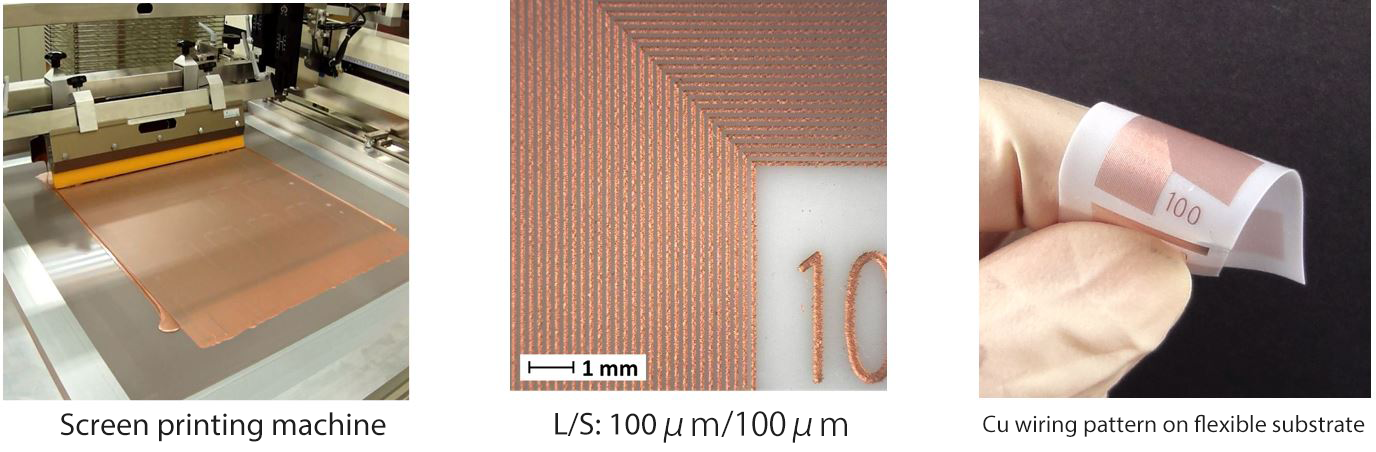

Fig. 1 Cu wiring pattern on plasma-irradiated PTFE using a Cu paste and screen printing machine

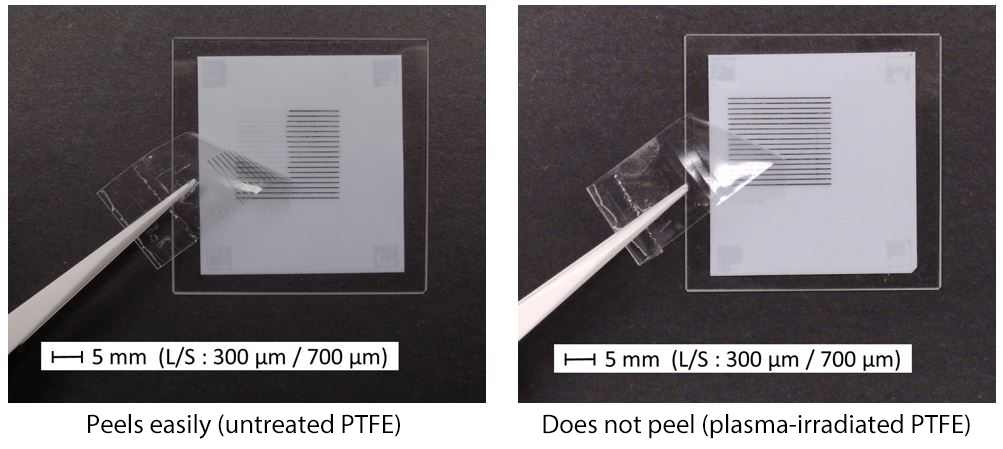

Fig. 2 Results of tape peel test of Ag wiring pattern on PTFE using a Ag salt ink and inkjet printing machine

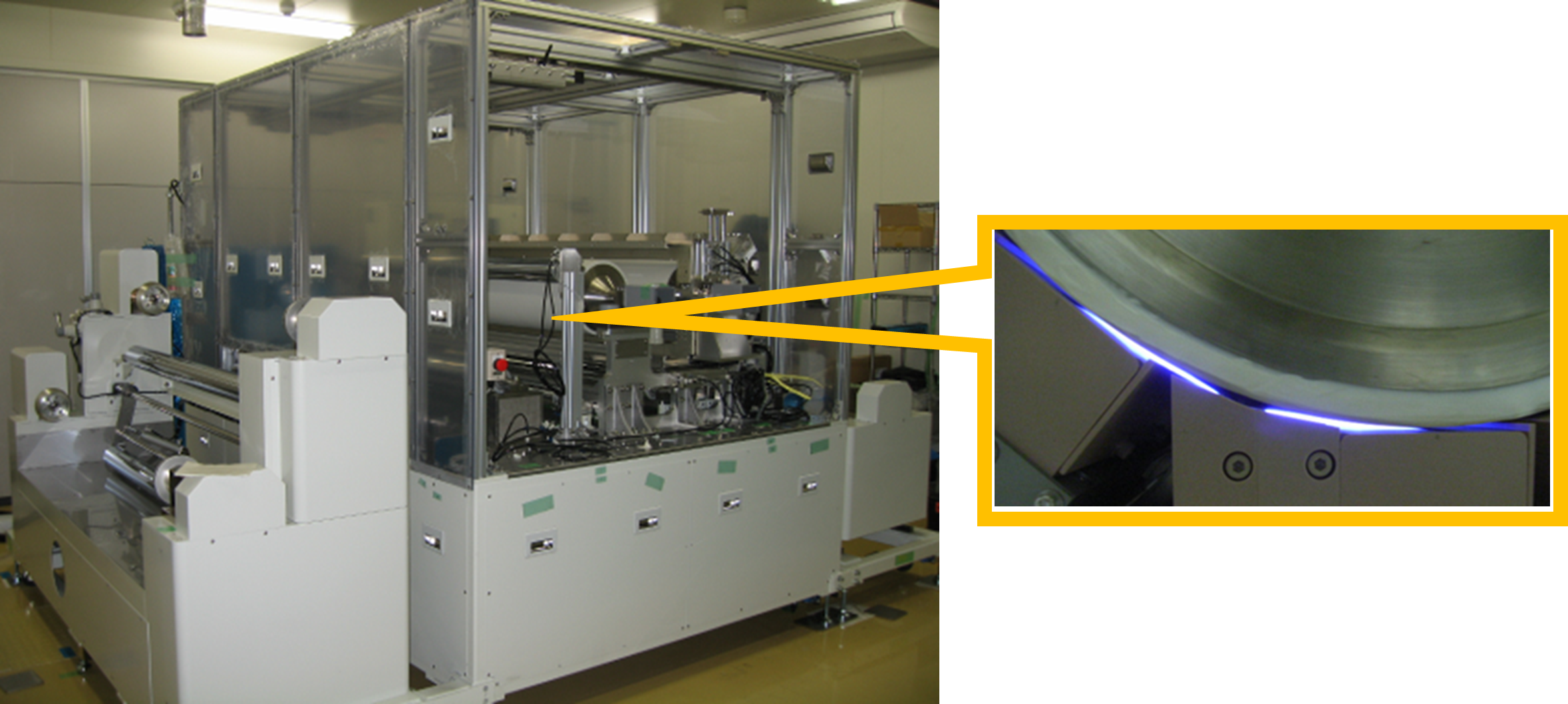

Fig. 3 Roll-to-Roll type atmospheric pressure plasma treatment system

Related Link