Construction of metabolic pathway of microorganisms — resulted in successful production of biofuel in a test tube

Under the leadership of HONDA Kousuke (Associate Professor, Graduate School of Engineering, Osaka University) a group of researchers succeeded in reconstructing in a test tube an artificial metabolic pathway for biofuel using 16 thermotolerant enzymes.

In producing substances by fermentation techniques, other than the desired substance(s), a variety of substances that microorganisms need for their growth are produced as by-products. If it were possible to extract only the metabolic enzymes necessary for producing the desired substances and construct an artificial metabolic pathway in a test tube, fermentation-based production would become possible without by-products.

A lot of labor and cost are required for selectively removing only necessary enzymes from the thousands of enzymes within an organism. Furthermore, in order to produce desired chemicals efficiently, rationally balance enzyme titers are needed; however, it has been difficult to achieve this balance by using only extracted enzymes.

This group addressed the development of a method for making an artificial metabolic pathway for producing useful chemicals when using thermotolerant enzymes. By developing a method to measure the flow of metabolism in the artificial pathway on a real-time basis, this group succeeded in rationally optimizing the amount of enzymes necessary for constructing the pathway. As a result, this group succeeded for the first time in producing butanol from glucose in a test tube using 16 thermotolerant enzymes.

The technique developed by this group is widely applicable to enzymes derived from thermophilic microorganisms so it can be applied to producing not only biofuels, but also a variety of other chemicals.

Abstract

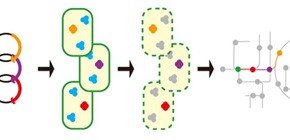

The heat treatment of recombinant mesophiles having heterologous thermotolerant enzymes results in the one-step preparation of highly selective biocatalytic modules. The assembly of these modules enables us to readily construct an artificial metabolic pathway in vitro. In this work, we constructed a non-natural, cofactor-balanced, and oxygen-insensitive pathway for n-butanol production using 16 thermotolerant enzymes. The whole pathway was divided into 7 parts, in each of which NAD(H)-dependent enzymes were assigned to be the last step, and the fluxes through each part were spectrophotometrically determined. This real-time monitoring technique enabled the experimental optimization of enzyme level to achieve a desired production rate. Through the optimized pathway, n-butanol could be produced from glucose with a molar yield of 82% at a rate of 8.2 µmol l−1 min−1. Our approach would be widely applicable to the rational optimization of artificial metabolic pathways as well as to the in vitro production of value-added biomolecules.

Figure 1

To learn more about this research, please read the full research report entitled " In vitro production of n-butanol from glucose " at this page of the Metabolic Engineering website.

Related links :